In the demanding world of metal forming, precision isn't optional—it’s a mandate. At the heart of high-performance rolling mills lie alloy cast steel rolls: the unsung titans engineered to endure the punishing forces of modern manufacturing. These rolls are not just components; they are the backbone of consistent output, dimensional accuracy, and operational efficiency.

The Anatomy of Durability

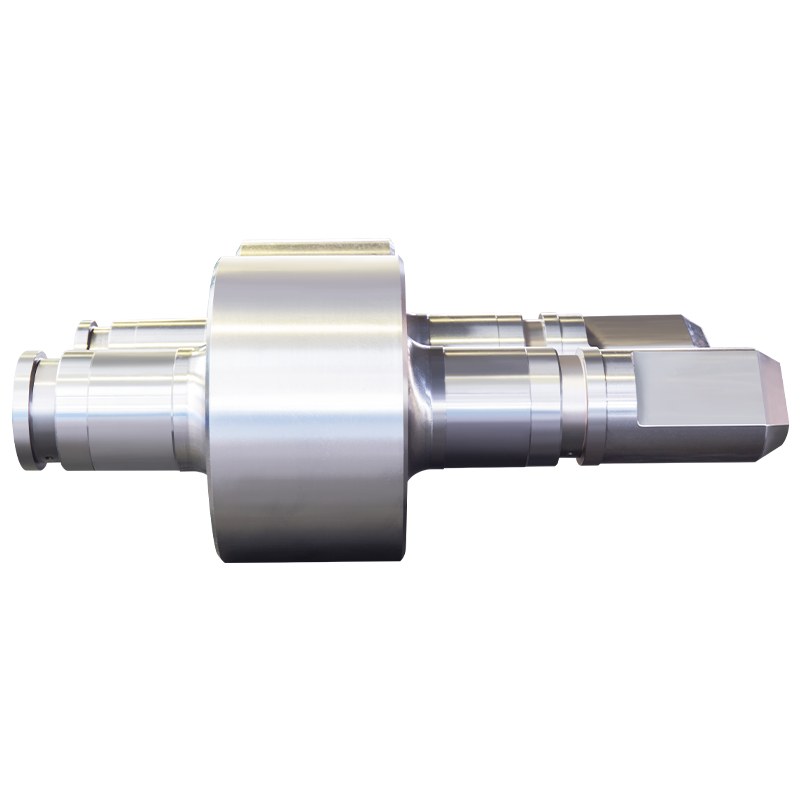

Alloy cast steel rolls are meticulously crafted from iron-based alloys enriched with chromium, molybdenum, nickel, and vanadium. This synergistic blend creates a microstructure that is both tenacious and wear-resistant, ideal for high-temperature, high-pressure environments. Unlike conventional steel rolls, alloy cast variants possess a fine balance between hardness and toughness, making them particularly suitable for intermediate and finishing stands of bar and section mills.

The casting process itself—often centrifugal or static casting—introduces density uniformity and eliminates metallurgical defects, ensuring structural integrity throughout the roll’s body. Post-casting treatments, such as annealing and tempering, further optimize the roll’s mechanical properties for specific mill applications.

Why Alloy Cast Steel Rolls Stand Apart

Their superiority lies not just in the metal, but in the performance. These rolls deliver outstanding resistance to thermal fatigue, surface cracking, and deformation. This is essential in rolling environments where temperature gradients are harsh and the contact pressures relentless.

Moreover, the alloy composition can be fine-tuned. For applications requiring elevated surface hardness without compromising core ductility, higher chrome and vanadium levels are introduced. In contrast, for operations favoring thermal conductivity and impact resistance, a molybdenum-rich configuration may be more suitable.

Applications That Demand Excellence

Alloy cast steel rolls are commonly deployed in hot strip mills, bar mills, and wire rod mills—industries where tolerances are razor-thin and downtime is unforgivable. Their ability to maintain profile consistency over extended runs reduces regrinding intervals, slashing maintenance costs and boosting overall productivity.

These rolls are also instrumental in rolling higher-grade steels and exotic alloys, where ordinary rolls would falter under stress. Whether shaping carbon steel or advanced high-strength steel (AHSS), alloy cast steel rolls consistently deliver smooth, precise results.

The Investment that Pays Back in Output

When considering total cost of ownership, alloy cast steel rolls offer measurable advantages. Their longer service life, minimal downtime, and enhanced performance translate into superior throughput. Add to this the operational stability they bring, and the return on investment becomes indisputable.

In a manufacturing landscape where precision, durability, and efficiency define competitive advantage, alloy cast steel rolls rise to the occasion. They are not merely components—they are strategic assets engineered to elevate the performance of every roll, every cycle, and every ton produced.