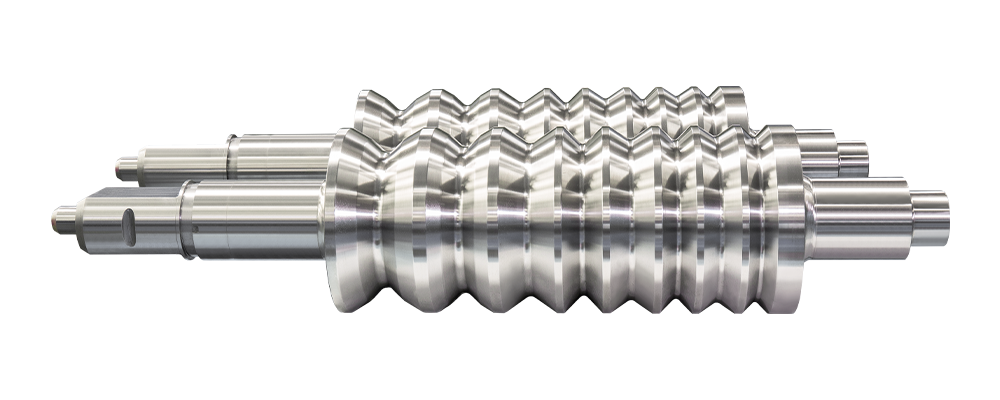

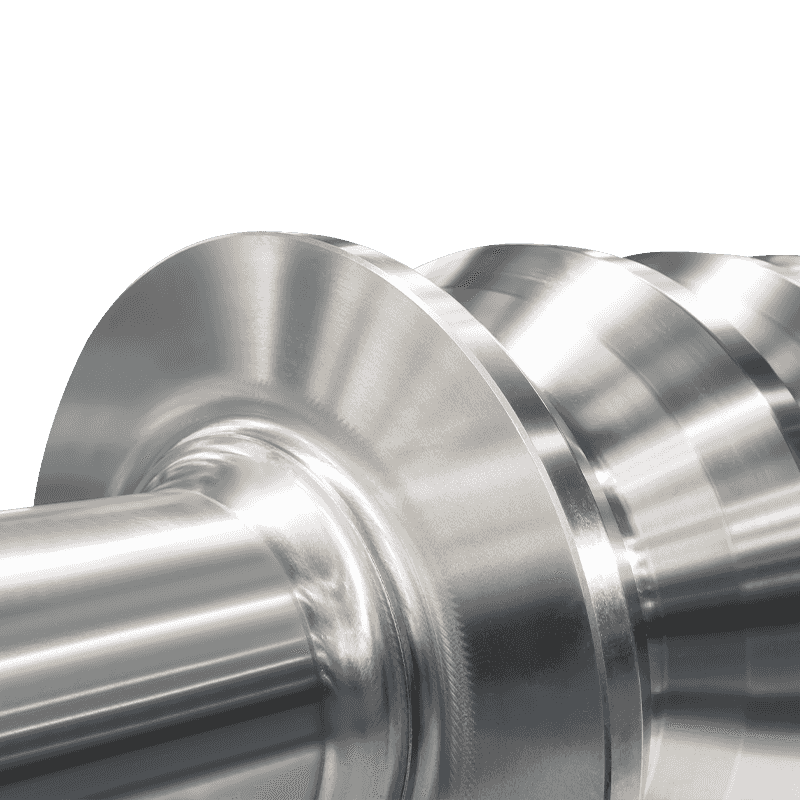

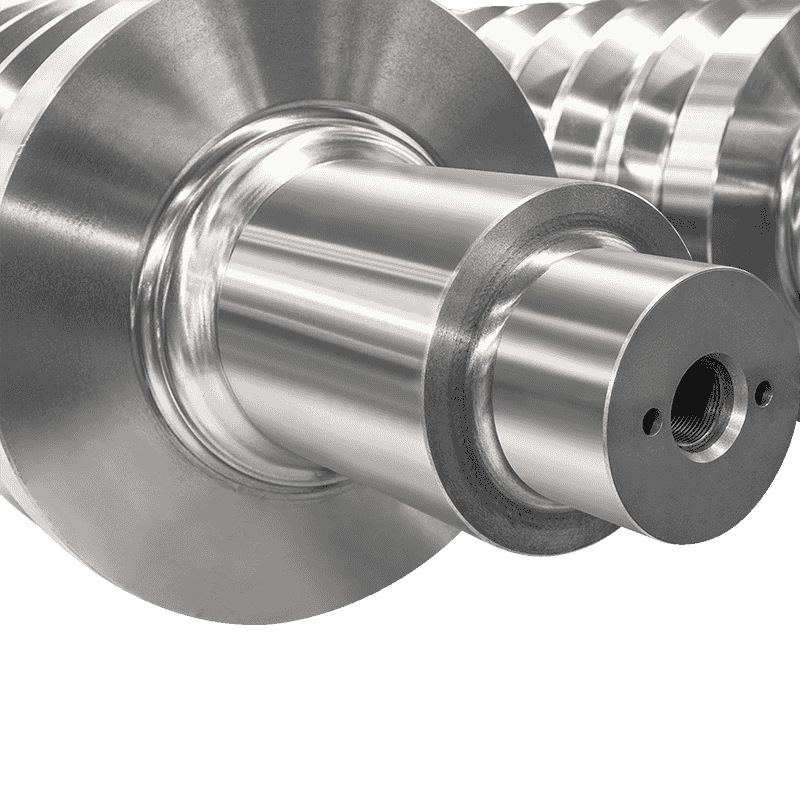

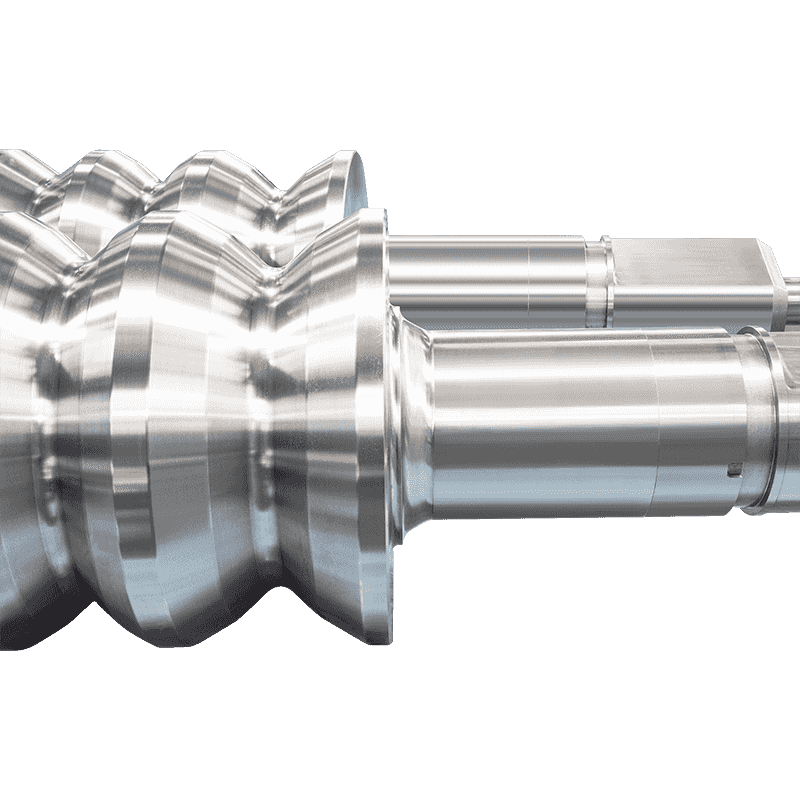

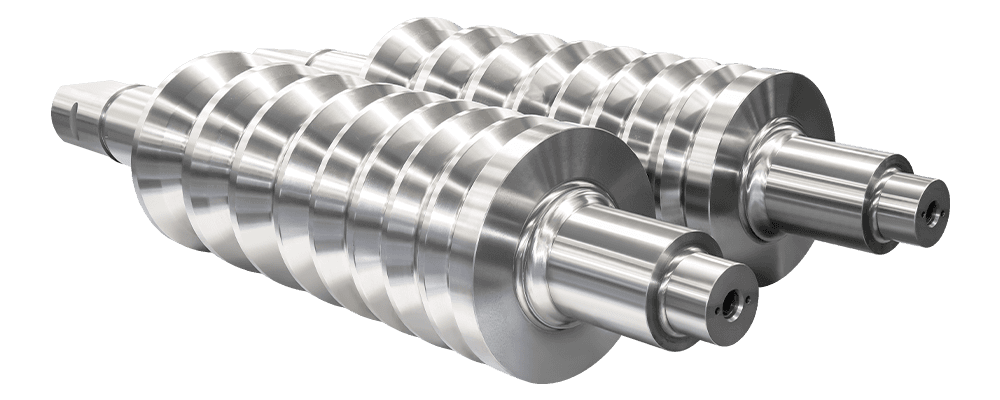

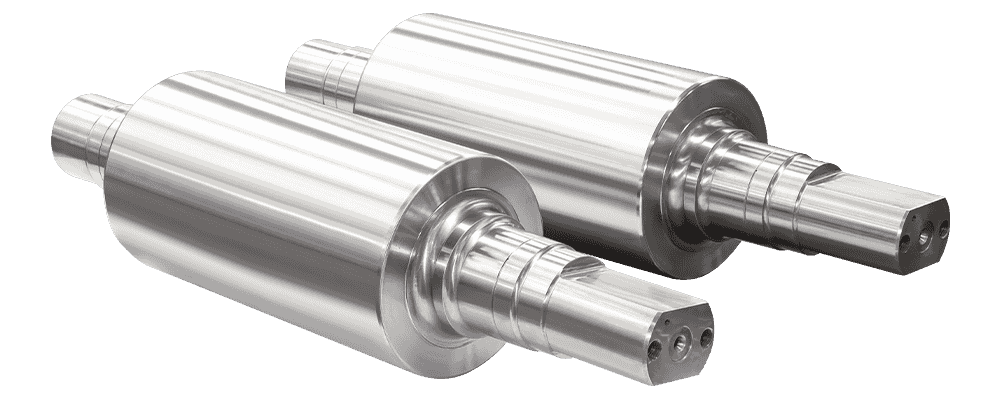

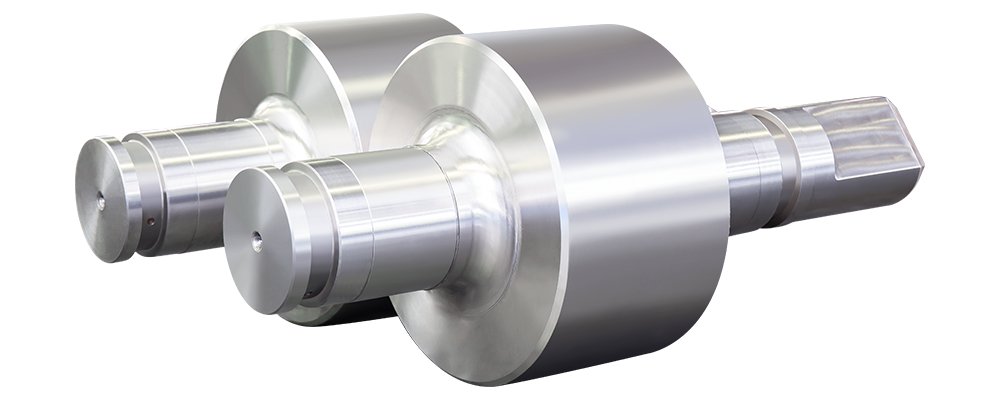

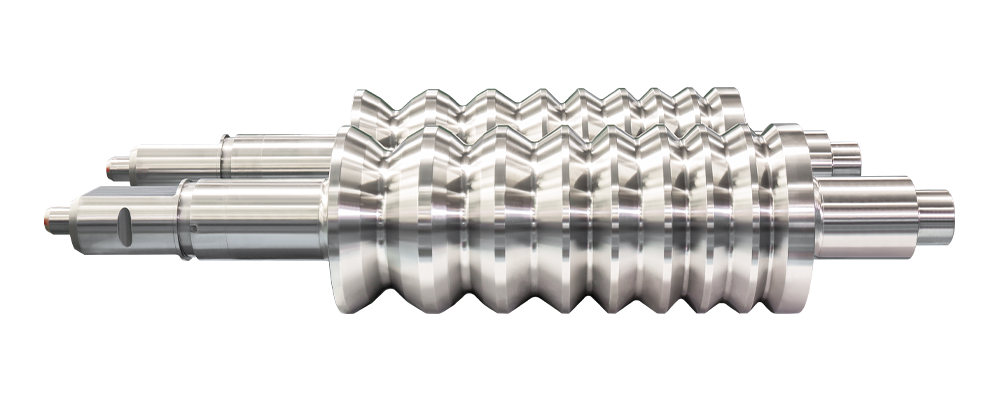

High-speed steel rolls are suitable for high-speed rolling processes, which can meet the needs of bar rolling mills for high-speed and efficient production and improve production efficiency. It can withstand the friction and wear of metal materials during high-speed rolling and extend the service life of the roll. It has high thermal conductivity and can quickly transfer heat to the roll surface, helping to control the temperature during the rolling process and improve rolling efficiency. It has good mechanical strength and impact resistance and can withstand the high pressure and impact load generated by metal materials during high-speed rolling. The use of high-speed steel rollers in bar rolling mills can improve production efficiency, reduce production costs, and ensure that the rolled bar products have surface quality and dimensional accuracy. Therefore, they have been widely used in the bar rolling industry.

Hardness HSD: 75-95

Nickel composition %: 0-1.5

Suitable for racks: Finishing rolls, pre-finishing rolls

Usage: Hot strip and bar finishing roll; section universal mills;pre-finishing stands of high-speed wire mill.

English

English 中文简体

中文简体