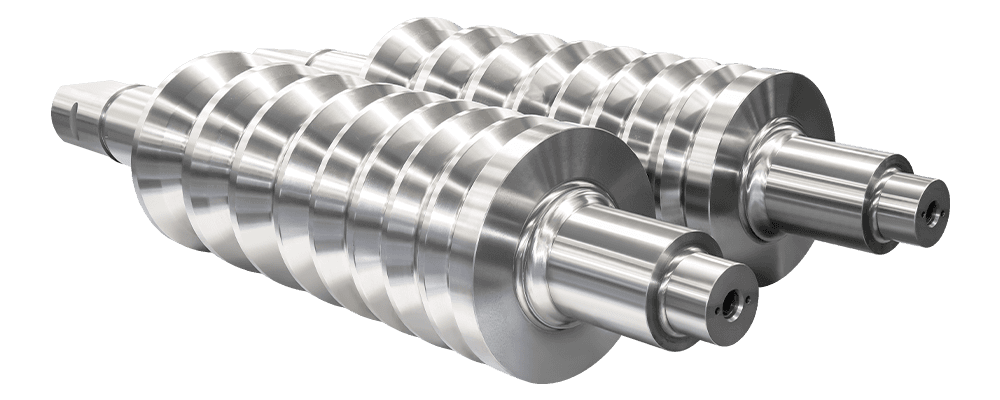

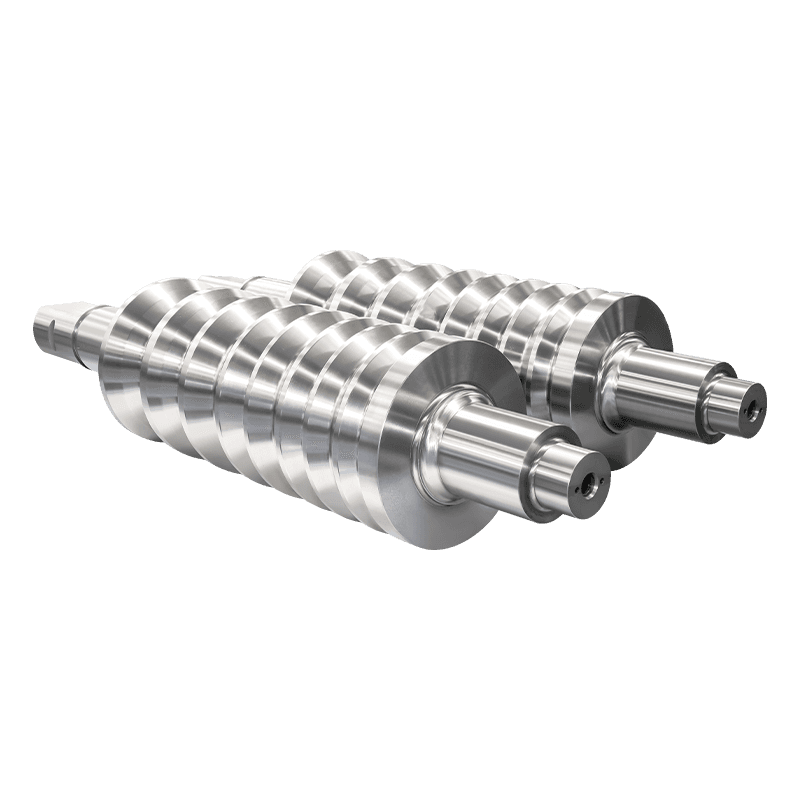

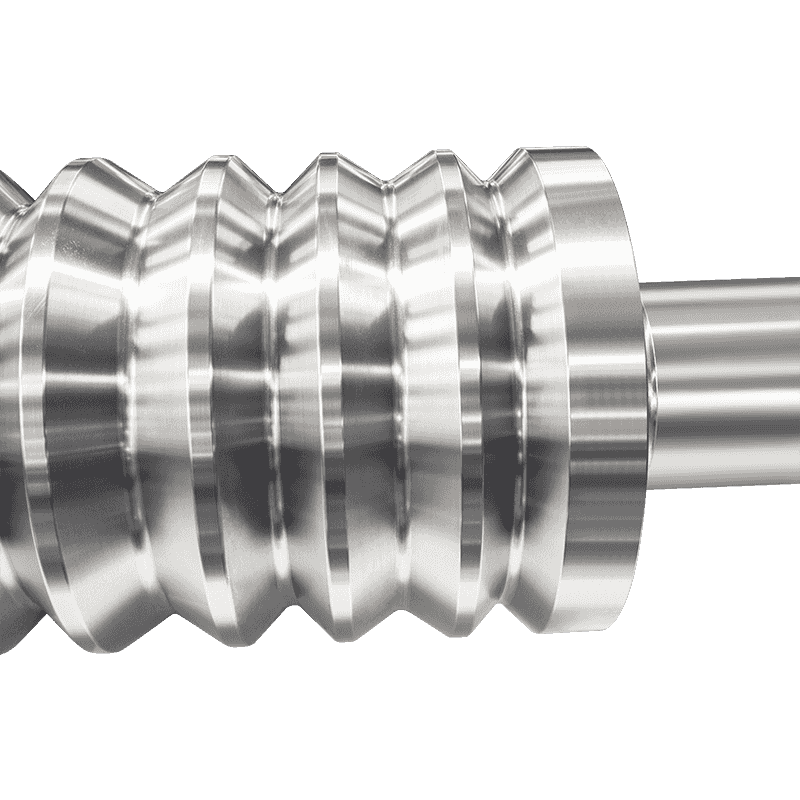

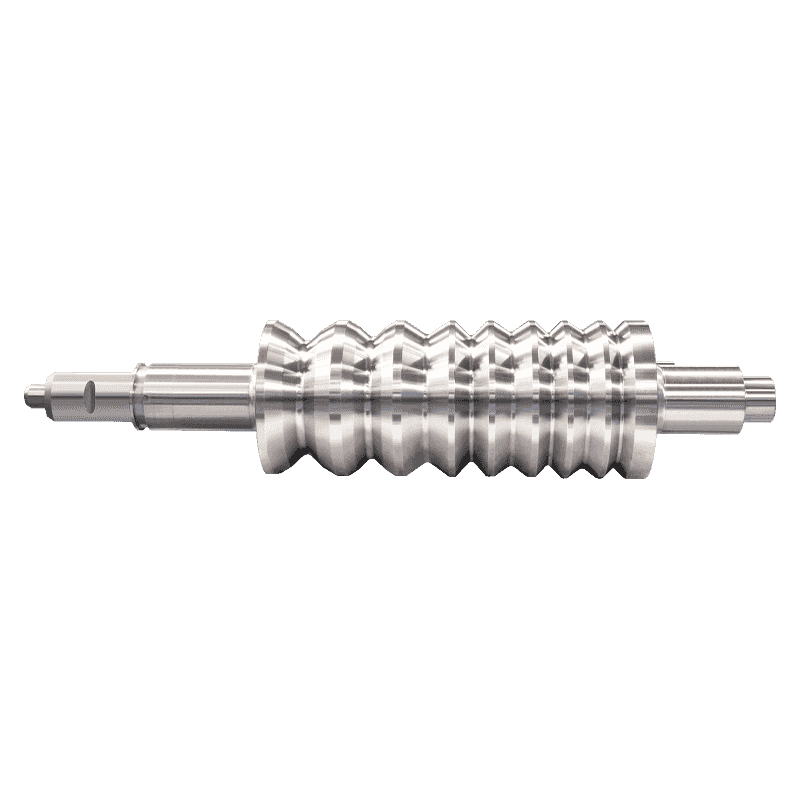

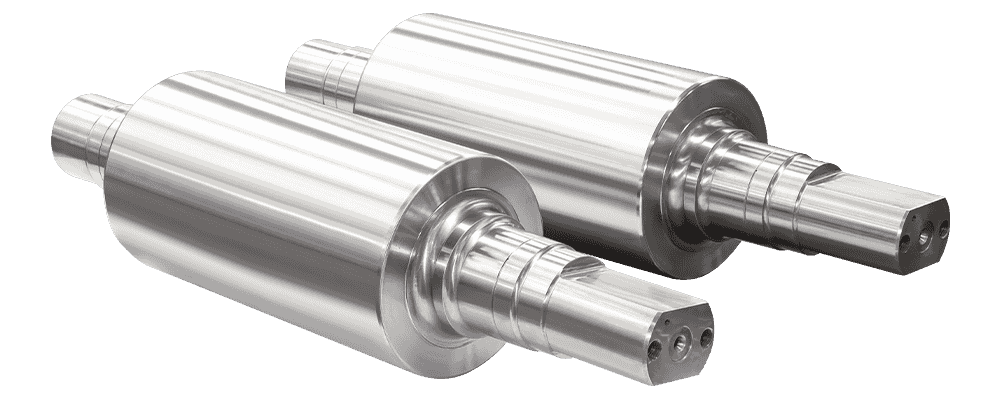

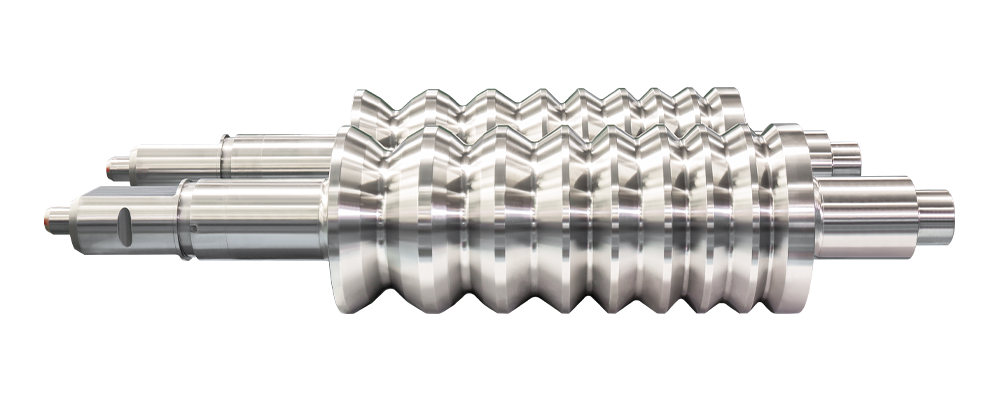

The hardness range of semi-high-speed steel rolls is usually between HSD 75 and 98. Rolls with different hardness can be selected according to different rolling processes and metal material requirements. The nickel content is between 0.2% and 1.2%. Nickel is a common alloying element that can increase the strength and hardness of steel, while also improving the corrosion resistance and thermal stability of steel. It is suitable for various rolling processes such as roughing, intermediate rolling, and finishing rolling, and can meet the rolling needs of different metal materials, including steel, aluminum, etc. Semi-high-speed steel rollers have high strength and hardness, can withstand the rolling process under high pressure and high speed, and have good wear resistance, extending the service life of the rolls. Semi-high-speed steel rolls are widely used in various metal rolling processes due to their wide hardness range, wide application range, high strength, and wear resistance. They are an important rolling equipment.

Hardness HSD: 75-98

Nickel composition %: 0.2-1.2

Suitable for racks: Rough-medium rolled, finish rolled

English

English 中文简体

中文简体