In the modern steel and metal rolling industry, one principle remains constant: every mill is unique. The type of metal being processed, the production speed, the rolling temperature, and the final product specifications all demand rolls that perform with precision and consistency. This raises an important question for mill operators and engineers alike — can a Cast Steel Roll be customized to meet specific mill requirements?

The answer is yes. Cast Steel Roll is among the most versatile and adaptable components in rolling mills today. Their composition, design, and treatment can be tailored to achieve optimal results in different production conditions. However, the process of customization involves much more than simply adjusting dimensions; it requires a thorough understanding of metallurgy, wear mechanisms, and mill dynamics.

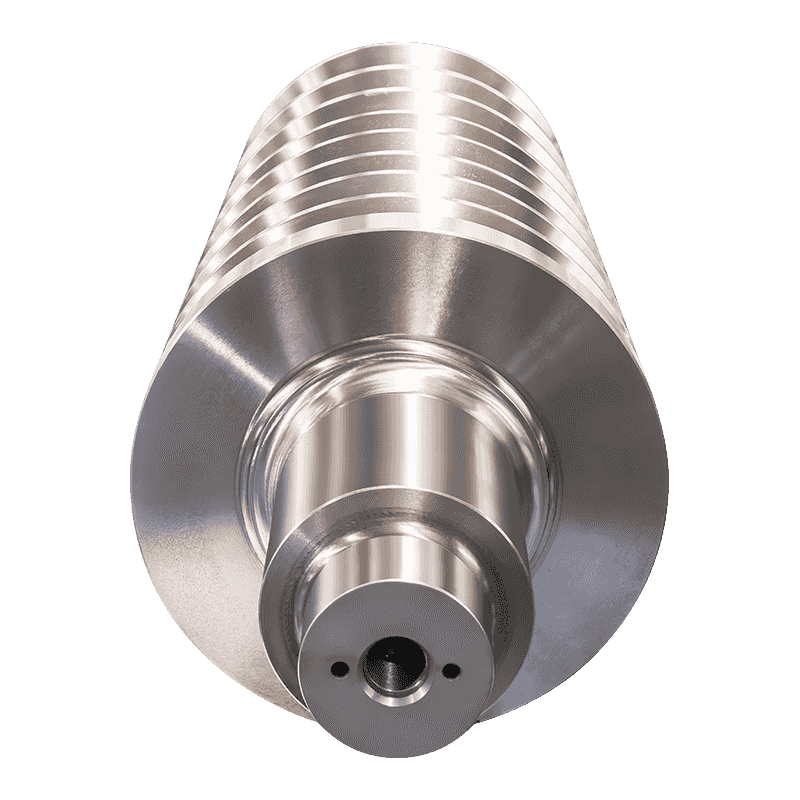

A Cast Steel Roll is a critical component used in rolling mills to shape and process materials such as steel, copper, aluminum, and other alloys. During rolling, the roll comes into direct contact with the heated or cold metal sheet, applying immense pressure to deform and flatten it to the desired thickness.

The performance of the roll directly influences surface quality, dimensional accuracy, and production efficiency. As a result, not all rolls can fit all mills — customization ensures that each roll meets the unique mechanical and operational demands of a particular mill setup.

Every mill operates under a distinct set of parameters, including rolling force, speed, temperature, and material hardness. These factors significantly affect the wear rate, surface finish, and overall performance of the roll.

Here are a few reasons customization is essential:

Different Rolling Conditions: Hot and cold rolling processes impose very different stresses on rolls. A roll designed for hot rolling needs to withstand thermal fatigue and oxidation, while a roll for cold rolling must resist surface wear and maintain dimensional precision.

Material Variability: The hardness and composition of the rolled metal determine the roll’s required hardness, microstructure, and surface characteristics.

Mill Design Differences: Rolling mills vary in configuration — from two-high to multi-high mills, and from plate mills to strip mills. Each setup demands different roll geometry, neck size, and core hardness.

Product Specifications: The desired surface finish, tolerance, and product thickness influence the roll surface roughness and hardness profile.

Customization allows manufacturers to optimize roll life, reduce downtime, and improve the consistency of finished products — all of which contribute to cost savings and operational efficiency.

The customization of a Cast Steel Roll involves several aspects — both in its composition and its mechanical design. Below are the main factors that can be adjusted based on specific mill requirements.

The alloy composition determines the roll’s fundamental properties such as hardness, wear resistance, and thermal stability. Common alloying elements include chromium, nickel, molybdenum, and vanadium.

For example:

By adjusting these alloying elements, manufacturers can fine-tune performance for a mill’s specific operating environment.

Roll hardness affects how the roll interacts with the workpiece and how well it resists deformation. Some mills require rolls with a hard surface and a softer core to absorb shocks — a design known as a gradient hardness profile.

Different mills may specify:

The hardness is typically adjusted through controlled heat treatment and alloy selection.

The microstructure — the internal arrangement of carbides, ferrite, and pearlite — influences a roll’s wear resistance and strength. For high-performance applications, rolls are heat-treated to create fine, evenly distributed carbides that enhance durability without becoming brittle.

Microstructure can be customized through changes in cooling rate during casting, alloy content, and subsequent heat treatment cycles.

Each mill stand has its own dimensional requirements, including roll barrel length, neck diameter, and journal design. Precision in these measurements ensures correct alignment, pressure distribution, and load bearing during rolling.

Some customization options include:

Surface treatments extend roll life and improve surface quality on the rolled material. Depending on the product, rolls can be:

Special coatings or surface hardening can also reduce sticking, scaling, or thermal cracking during high-temperature rolling.

The roll’s internal structure — particularly the core — determines its toughness and resistance to breakage. For mills operating under heavy loads or frequent thermal cycling, a tougher, ductile core is essential. Manufacturers may use specific casting and cooling methods to ensure the right balance between strength and flexibility.

Customization begins with a clear understanding of the mill’s operational environment. Typically, the process involves collaboration between the mill engineers and the roll manufacturer.

Step 1: Needs Assessment

The mill provides detailed specifications — including material types, rolling speed, reduction rate, operating temperatures, and roll stand positions.

Step 2: Material Selection and Design

Based on these parameters, metallurgists recommend suitable steel grades and alloying compositions. CAD models and simulations may be used to design the roll’s geometry and predict performance.

Step 3: Casting and Heat Treatment

The chosen design is then cast, often through static casting or centrifugal casting, depending on the roll type. Heat treatment follows to achieve the desired hardness and microstructure.

Step 4: Machining and Surface Finishing

After heat treatment, the roll undergoes precision machining and surface polishing to match dimensional and surface finish requirements.

Step 5: Quality Testing

Every customized roll is rigorously tested for internal flaws, hardness distribution, surface integrity, and dimensional accuracy before delivery.

When properly designed, a customized Cast Steel Roll offers measurable benefits that directly impact mill efficiency and product quality:

Ultimately, customization aligns the roll’s properties with the mill’s unique production strategy, enhancing both performance and cost-effectiveness.

While customization brings many benefits, it must be approached with technical care. Several challenges can arise if specifications are unclear or unrealistic:

To avoid such issues, collaboration between metallurgical experts and mill operators is crucial from the design stage onward.

Selecting a manufacturer capable of genuine customization is just as important as defining the roll specifications. Here’s what to look for:

As rolling technologies evolve, so does the customization potential of Cast Steel Rolls. The industry is moving toward digital integration, where simulation software, AI-based wear prediction, and data analytics are used to design rolls optimized for specific production lines.

Additive manufacturing techniques are also being explored to enhance surface coatings and repair processes. In the near future, mills may use predictive modeling to adjust roll properties even before production begins — reducing trial time and improving consistency.

So, can a Cast Steel Roll be customized according to specific mill requirements? Absolutely — and in most modern rolling operations, it should be.

Customization transforms a standard roll into a precision-engineered tool tailored to the mill’s exact working conditions. By fine-tuning chemical composition, hardness, geometry, and surface properties, mills can achieve higher productivity, better product quality, and reduced maintenance costs.

However, successful customization requires collaboration, expertise, and attention to detail. The key lies in clearly defining operational parameters, partnering with an experienced manufacturer, and understanding that the best roll isn’t just strong — it’s designed specifically for the job it performs.

In the competitive world of metal rolling, customized Cast Steel Rolls aren’t a luxury — they are an essential step toward consistent quality, efficient operation, and long-term cost savings.