Cast steel roll is a crucial component in rolling mills, shaping metals in hot and cold rolling processes. Their performance directly affects production efficiency, product quality, and equipment lifespan. One of the most challenging operational stresses these rolls face is repeated thermal cycling—rapid heating and cooling during operation. Understanding how cast steel rolls respond to thermal cycles is vital for manufacturers, maintenance teams, and engineers.

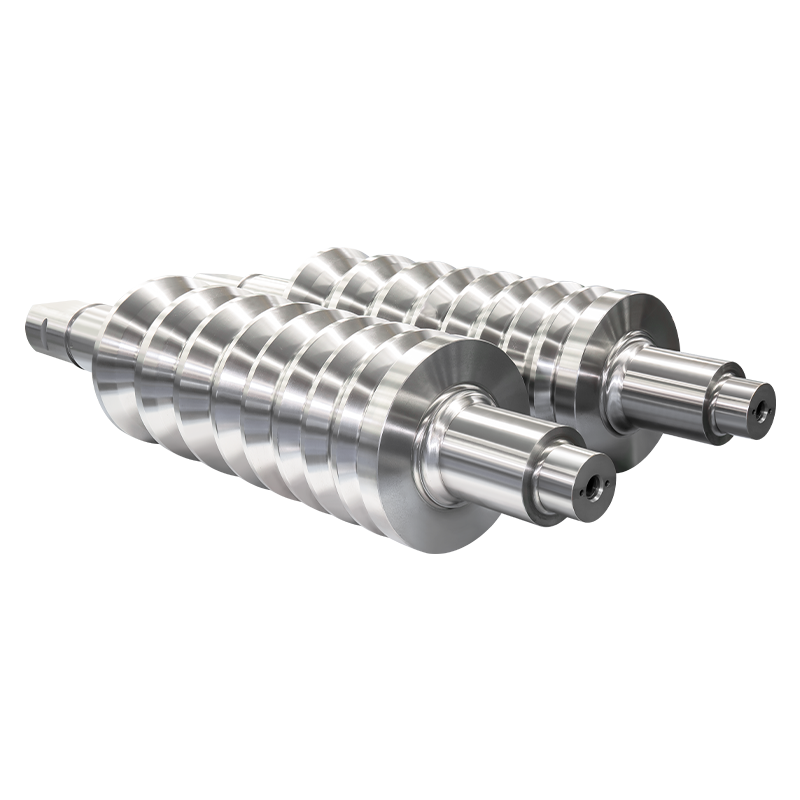

A cast steel roll is a cylindrical component made by casting molten steel into a mold. Unlike forged rolls, which are shaped by compressive forces, cast rolls rely on the solidification of liquid steel, allowing for complex geometries and larger dimensions. Cast steel rolls are widely used in hot rolling mills due to their strength, wear resistance, and ability to handle high loads.

Thermal cycling occurs when rolls are exposed to repeated heating and cooling during production. In hot rolling, the roll surface contacts heated metal slabs, rapidly increasing its temperature. After passing the metal, the roll may cool via ambient air, water sprays, or lubrication systems. This constant temperature fluctuation causes expansion and contraction in the material, leading to thermal stress.

Cast steel rolls contain alloying elements such as chromium, molybdenum, and nickel to improve heat resistance and toughness. Properly selected alloy grades can withstand repeated heating and cooling without significant degradation. For example:

After casting, rolls undergo heat treatment processes like quenching and tempering. This process refines the microstructure, relieves residual stresses from casting, and enhances thermal fatigue resistance. A properly heat-treated cast steel roll can endure thousands of thermal cycles before surface cracks appear.

Surface coatings or nitriding can improve thermal resistance further. These treatments reduce oxidation, maintain hardness, and extend roll life under repeated thermal loading.

While cast steel rolls are engineered to handle repeated thermal cycles, their performance depends on operational conditions:

In practice, a high-quality cast steel roll in a well-maintained mill can withstand tens of thousands of thermal cycles before major maintenance or replacement is required. However, ignoring cooling rates, thermal gradients, or surface defects can significantly shorten the roll’s life.

Cast steel rolls are designed to endure repeated thermal cycles, but their longevity depends on material composition, heat treatment, surface quality, and operational management. Properly manufactured and maintained cast steel rolls can provide years of reliable service, even under harsh thermal conditions. For rolling mills, investing in high-quality rolls and following best practices for operation and maintenance ensures consistent performance, improved product quality, and reduced downtime.