Cast iron roll is essential components in many industrial and manufacturing processes. They are widely used in rolling mills, metalworking facilities, and other production environments where strength, precision, and durability are crucial. Understanding the properties, design considerations, and maintenance practices for cast iron rolls is essential for maximizing their performance and lifespan.

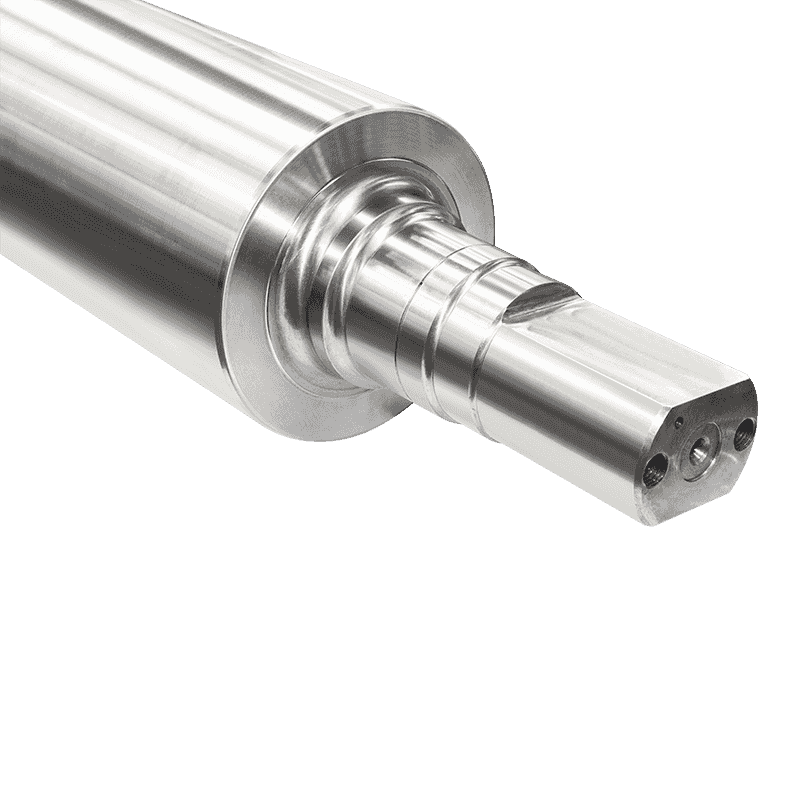

Cast iron rolls are cylindrical components made primarily from cast iron, a material known for its compressive strength, wear resistance, and ability to dampen vibrations. They serve as critical tools in shaping, compressing, or processing metals, paper, plastics, and other materials. Their applications range from heavy industrial rolling mills to smaller machinery in specialized manufacturing processes.

The material properties of cast iron contribute to its widespread use in roll manufacturing. Gray cast iron, for example, contains graphite flakes that provide excellent vibration damping, which is particularly beneficial in reducing noise and maintaining precision in high-speed operations. White cast iron, on the other hand, is harder and more wear-resistant but less capable of absorbing vibrations. Selecting the appropriate type of cast iron for a specific application is a key factor in achieving the right balance between strength and durability.

Several key properties of cast iron affect the performance of rolls:

Compressive Strength: Cast iron can withstand significant pressure without deforming, making it ideal for applications that require high mechanical stress.

Wear Resistance: Depending on the grade, cast iron offers excellent resistance to abrasion and surface wear. This ensures that rolls maintain their shape and functionality over long periods.

Thermal Conductivity: Cast iron rolls can efficiently dissipate heat generated during processing, preventing thermal expansion and deformation.

Damping Capacity: The graphite content in certain cast iron types allows rolls to absorb vibrations, improving surface finish quality and reducing noise in production environments.

Understanding these properties is crucial for engineers and maintenance teams when selecting and operating cast iron rolls in industrial settings.

Cast iron rolls are used in a variety of industrial sectors due to their strength, precision, and durability. Common applications include:

Metal Rolling Mills: Cast iron rolls shape metal sheets, plates, and bars by applying uniform pressure during rolling operations. Their high compressive strength and wear resistance make them suitable for continuous operation under heavy loads.

Paper and Pulp Industry: Rolls made from cast iron help in pressing and calendering paper, ensuring consistent thickness and surface finish.

Plastic and Rubber Processing: Cast iron rolls are used in rolling mills for plastic sheets and rubber compounds, providing stability and uniform pressure.

Textile Industry: Some machinery relies on cast iron rolls to process fibers and fabrics, ensuring smooth operation and reducing mechanical vibrations.

These applications demonstrate the versatility of cast iron rolls and highlight the importance of matching roll material and design to specific operational requirements.

Designing cast iron rolls involves balancing multiple factors to ensure both strength and durability. Key considerations include:

Material Selection: Choosing the right type of cast iron is critical. Gray cast iron is often preferred for general applications due to its damping properties, while white cast iron is used in high-wear environments. Alloyed cast iron may offer improved hardness and resistance to deformation.

Roll Dimensions: The diameter, length, and wall thickness of the roll affect its load-bearing capacity and resistance to bending. Oversized rolls may offer strength but can increase weight and cost, while undersized rolls may wear out quickly.

Surface Treatment: Hardening, nitriding, or applying wear-resistant coatings can extend the life of cast iron rolls without compromising their structural integrity. Proper surface finishing also improves performance in high-friction applications.

Balancing and Alignment: Rolls must be precisely balanced and aligned to prevent uneven wear, vibration, and premature failure. Even minor deviations can reduce efficiency and increase maintenance requirements.

By carefully considering these factors during design, manufacturers and engineers can optimize cast iron rolls for both strength and durability, ensuring reliable performance over time.

Even the strongest and most durable cast iron rolls require proper maintenance to achieve their full lifespan. Maintenance practices include:

Regular Inspection: Monitoring for cracks, surface wear, or corrosion helps identify potential issues before they lead to failure. Visual inspections, ultrasonic testing, and hardness measurements are commonly used techniques.

Lubrication: Proper lubrication reduces friction and wear, especially in high-speed operations. Selecting the right lubricant and applying it consistently is essential.

Cleaning: Keeping rolls free from debris, scale, or chemical residues prevents surface damage and ensures consistent operation.

Reconditioning: Over time, worn rolls may require grinding or resurfacing to restore their dimensions and surface quality. This extends their operational life without the need for complete replacement.

Environmental Control: Minimizing exposure to moisture, chemicals, or extreme temperatures reduces corrosion and thermal damage, preserving both strength and durability.

Routine maintenance not only prolongs roll life but also improves operational efficiency and reduces downtime in production processes.

Despite their advantages, cast iron rolls can face several challenges that may compromise their strength and durability if not addressed properly:

Cracking: Thermal stress, improper handling, or overloading can lead to cracks. Using appropriate cooling methods, handling techniques, and load limits helps prevent this issue.

Wear and Deformation: Continuous operation under heavy loads may cause surface wear or deformation. Applying hard coatings or alloying the cast iron can improve wear resistance.

Corrosion: Cast iron is susceptible to rust in humid or chemically aggressive environments. Protective coatings and regular cleaning mitigate corrosion risks.

Imbalance and Vibration: Misaligned or unbalanced rolls can cause uneven wear and damage to machinery. Proper installation, alignment, and balancing are essential.

Addressing these challenges through careful design, operation, and maintenance ensures that cast iron rolls perform reliably throughout their intended service life.

When selecting cast iron rolls, several factors should guide decision-making:

Application Requirements: Consider load, speed, temperature, and environmental conditions.

Material Grade: Choose the type of cast iron that balances strength, wear resistance, and damping properties.

Surface Finish: Specify the required hardness and smoothness for optimal performance.

Replacement and Maintenance Strategy: Evaluate the ease of maintenance and expected lifespan to minimize downtime and operational costs.

Making informed choices in the selection process helps organizations achieve operational efficiency while maintaining the strength and durability of their cast iron rolls.

Cast iron rolls are indispensable in many industrial applications due to their exceptional strength, wear resistance, and ability to dampen vibrations. Achieving the right balance between strength and durability requires careful attention to material selection, design, and maintenance practices. By understanding the properties and applications of cast iron rolls, manufacturers can optimize performance, extend service life, and reduce operational costs. Proper inspection, lubrication, cleaning, and reconditioning further enhance the durability of these essential components.

In the competitive and demanding world of industrial production, investing in the right cast iron rolls and maintaining them effectively is not just a matter of performance but also a strategic approach to reliability and cost efficiency. By balancing strength and durability, cast iron rolls continue to play a critical role in ensuring the smooth operation of machinery and the consistent quality of finished products.