Cast steel roll are critical components in metalworking industries, particularly in rolling mills. They offer a cost-effective solution with excellent wear resistance, toughness, and thermal stability. This article explores the properties, manufacturing processes, and key applications of cast steel rolls while comparing them with alternative roll types.

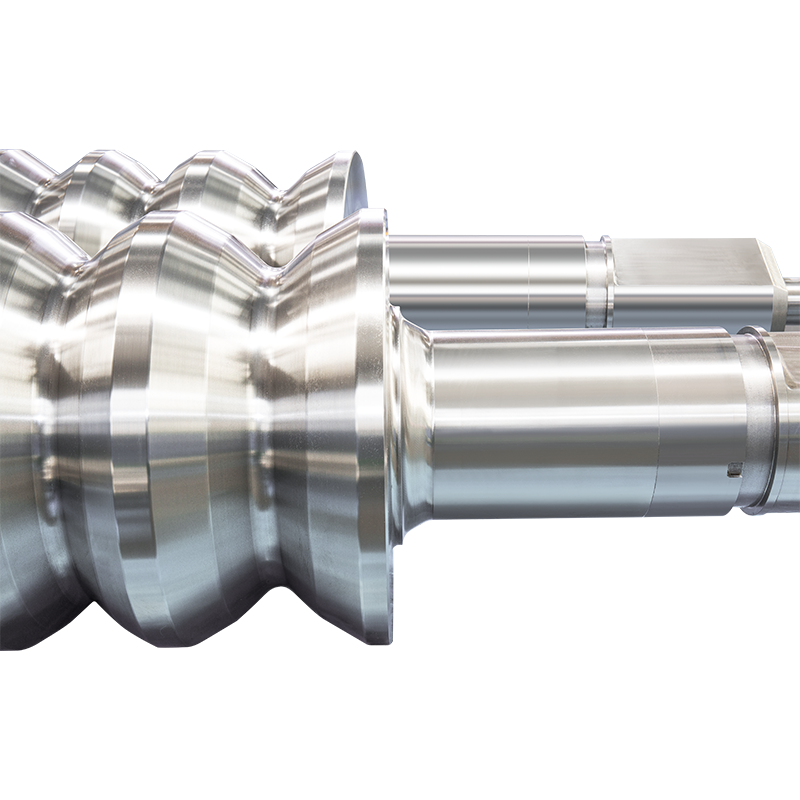

A cast steel roll is a cylindrical tool used in rolling mills to shape, reduce thickness, or impart surface finishes to metal products. These rolls are produced through casting methods, offering distinct advantages in certain industrial applications.

Cast steel rolls possess several important characteristics that make them suitable for demanding industrial applications:

| Property | Description | Importance |

|---|---|---|

| Hardness | Typically 35-85 HS (Hardness Shore) | Determines wear resistance |

| Toughness | High impact resistance | Prevents cracking under stress |

| Thermal Stability | Maintains properties at high temps | Essential for hot rolling |

| Wear Resistance | Superior to many cast iron rolls | Extends service life |

The production of high-quality cast steel rolls involves several precise steps:

Wooden or metal patterns are created to form the mold cavity for the roll.

Sand molds are prepared using the patterns, typically using resin-bonded sand for better surface finish.

Steel is melted in electric arc furnaces at temperatures around 1600°C (2912°F) and carefully poured into molds.

The cooling rate is controlled to achieve desired microstructure and minimize internal stresses.

Rolls undergo processes like quenching and tempering to achieve optimal mechanical properties.

Final dimensions and surface finish are achieved through turning, grinding, and polishing.

Ultrasonic testing, hardness measurements, and dimensional checks ensure product quality.

Cast steel rolls serve in various industrial sectors:

| Industry | Application | Roll Type |

|---|---|---|

| Steel Production | Hot rolling mills | Backup rolls, work rolls |

| Non-Ferrous Metals | Aluminum rolling | Intermediate rolls |

| Metal Processing | Plate rolling | Large diameter rolls |

| Wire Production | Rod mills | Grooved rolls |

Compared to other roll types, cast steel rolls offer several benefits:

Lower production costs compared to forged rolls, especially for large diameters.

Complex internal cooling channels can be incorporated during casting.

Alloy composition can be precisely controlled for specific applications.

Can be produced in sizes difficult to achieve through forging.

Understanding the differences helps in selecting the right roll type:

| Parameter | Cast Steel Rolls | Forged Steel Rolls |

|---|---|---|

| Production Method | Casting | Forging |

| Grain Structure | Larger grains | Fine, directional grains |

| Cost | Generally lower | Higher |

| Size Limitations | Fewer restrictions | Limited by forging capacity |

| Best For | Large diameters, complex shapes | High-stress applications |

Proper maintenance extends roll life and maintains product quality:

Check for surface cracks, wear patterns, and dimensional changes.

Store horizontally on padded racks in dry conditions to prevent warping and rust.

Use appropriate lifting equipment to avoid impact damage.

Implement proper cleaning and lubrication procedures during use.

Remove surface defects before they propagate into deeper cracks.

Understanding failure mechanisms helps in prevention:

| Failure Type | Causes | Prevention Methods |

|---|---|---|

| Spalling | Fatigue, overloading | Proper hardness selection |

| Thermal Cracking | Rapid temperature changes | Controlled cooling |

| Wear | Abrasive contact | Hardfacing or coatings |

| Breakage | Impact, defects | Quality control |

Innovations continue to improve roll performance:

New compositions offer better combinations of hardness and toughness.

Computer-controlled processes ensure more consistent properties.

Advanced NDT methods detect smaller flaws earlier.

Laser treatments and coatings extend service life.

Consider these factors when choosing rolls for your application:

| Factor | Consideration |

|---|---|

| Rolling Process | Hot vs. cold rolling requirements |

| Material Being Rolled | Hardness and abrasiveness |

| Production Volume | High volume needs more wear-resistant rolls |

| Mill Configuration | Roll positioning and stresses |

| Budget | Initial cost vs. total lifecycle cost |

Cast steel rolls remain essential components in metal rolling operations, offering a balance of performance and cost-effectiveness. Understanding their properties, manufacturing processes, and proper application helps industries maximize their value. With ongoing technological advancements, cast steel rolls continue to evolve, meeting the ever-increasing demands of modern metal processing.

Service life varies widely (from weeks to years) depending on application conditions, material rolled, and maintenance practices.

Yes, techniques like hardfacing and grinding can extend service life, depending on the damage extent.

Higher carbon generally increases hardness but reduces toughness. Optimal balance depends on specific application needs.

Typically 8-12 weeks for standard sizes, longer for custom or large diameter rolls.

Yes, their longer service life and recyclability contribute to reduced environmental impact compared to frequent replacements.