In the colossal, fiery heart of the modern steel mill, where raw materials are transformed into the backbone of our civilization—the I-beams for skyscrapers, the panels for automobiles, the sheets for appliances—a quiet but critical revolution is always underway. While much attention is given to the massive furnaces, sophisticated automation, and advanced metallurgy, the success of the entire operation often hinges on a more humble, yet profoundly complex, component: the cast iron roll.

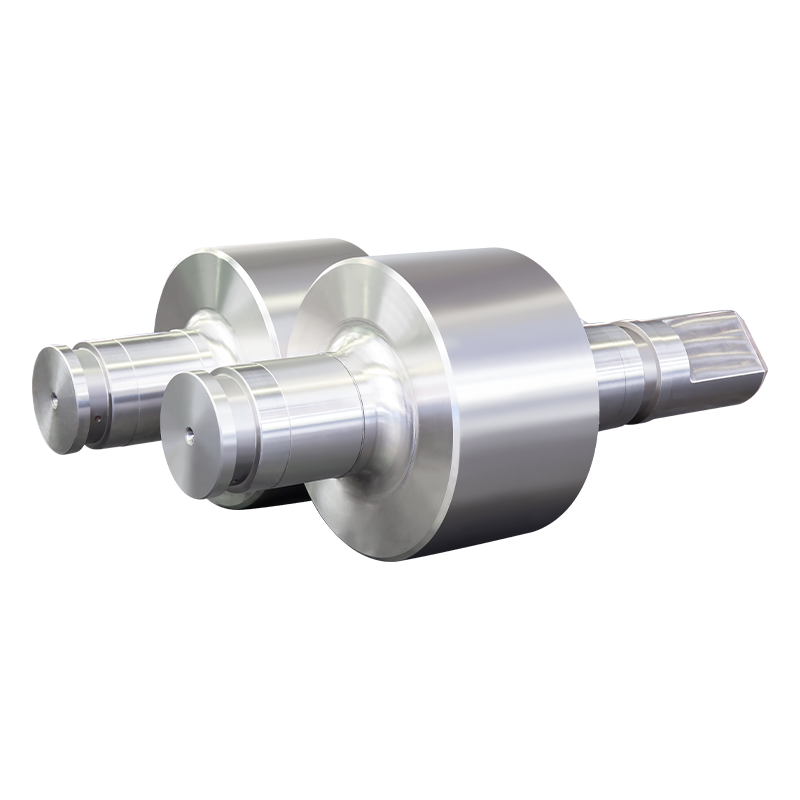

These are not simple cylinders of metal. They are precisely engineered masterpieces of foundry science, designed to withstand unimaginable forces, extreme temperatures, and relentless abrasion.

At its core, a rolling mill operates on a simple principle: to reduce the thickness of a steel slab or billet by passing it through two or more counter-rotating rolls. The immense pressure applied shapes and elongates the steel. The rolls themselves are the direct point of contact, the interface between machine and product. Their performance dictates the mill’s efficiency, product quality, and operational cost.

Cast iron has been the material of choice for certain rolling applications for over a century due to its unique combination of properties:

Excellent Wear Resistance: The graphite flakes or nodules within the iron matrix act as a natural lubricant and provide superior resistance to the abrasive action of hot scale and hard steel.

Good Thermal Resistance: Cast iron can absorb and dissipate the intense heat from the steel workpiece without significant loss of structural integrity.

Superior Surface Finish: The microstructure of certain cast irons allows them to impart a high-quality, consistent surface finish onto the rolled steel product.

Machinability and Cost-Effectiveness: Compared to some forged steel rolls, certain types of cast iron rolls are more economical to produce and machine to precise dimensions.

Not all rolling stands are created equal, and neither are the rolls that run in them. The specific demands of each mill stand—from the roughing stands that bite into red-hot slabs to the finishing stands that deliver the final, precise gauge—require different roll characteristics. The metallurgy of cast iron rolls has evolved to meet these needs.

1. Indefinite Chill (IC) Double Poured Rolls: This is a workhorse of the hot rolling industry, particularly in the intermediate stands of a bar mill or the early finishing stands of a section mill. The name “double poured” refers to the manufacturing process where the core of the roll is poured from one type of iron (often a spheroidal graphite iron for strength and toughness), while the outer shell is poured from a harder, wear-resistant indefinite chill iron. This creates a perfect synergy: a tough core to withstand bending forces and a hard shell to resist wear. The “indefinite chill” microstructure features a network of carbides in a matrix that transitions from martensite to pearlite, providing a unique combination of hardness and resistance to thermal shock.

2. High-Chrome Iron Rolls: For the most demanding applications, particularly in the finishing stands of a hot strip mill, high-chrome iron rolls are the premium choice. Alloyed with 12% to 22% chromium, these rolls develop a high volume of hard, complex chromium carbides (e.g., M7C3) embedded in a martensitic matrix. This structure offers exceptional wear resistance and, crucially, a consistent surface roughness retention over a long campaign life. This consistency is key to maintaining a uniform surface finish on the strip steel throughout the roll’s service interval. They are a critical component for achieving high-quality thin gauge strip production.

3. Spheroidal Graphite (SG) Iron Rolls (Nodular Iron Rolls): Where shock resistance and strength are paramount, SG iron rolls excel. The graphite within their microstructure is in the form of spheroids (nodules) rather than flakes, which drastically increases tensile strength and toughness. This makes them ideal for roughing mill stands, where they must endure extreme mechanical and thermal shocks as they first bite into the workpiece. They are also commonly used as backup rolls in 4-high or cluster mills, where their primary job is to provide rigid support to the smaller work rolls without fracturing under tremendous bending forces.

4. Adamite Rolls: A general-purpose category of cast iron rolls, adamite rolls are alloyed with elements like nickel, molybdenum, and chromium to achieve a balance of hardness, strength, and depth of hardness. They are often used in less severe applications, such as certain long product rolling mills or as rebar mill rolls.

The creation of a high-performance cast iron roll is a meticulous process blending ancient foundry techniques with modern metallurgical science.

Pattern Making: A precise wooden or metal pattern is created, which is slightly larger than the final roll dimensions to account for shrinkage during cooling.

Molding: The pattern is used to create a mold in sand. For double-poured rolls, this process is exceptionally complex, requiring a pre-core and specific molding techniques to allow for the two separate pours.

Melting and Pouring: Raw materials are melted in a furnace (often an electric induction furnace for precise control). Alloying elements are added to the melt to achieve the exact chemical composition. The molten metal is then poured into the mold at a carefully controlled temperature. For centrifugally cast composite rolls, the mold is spun at high speed during pouring, forcing the denser metal to the outer wall to form the shell, while a different material is poured statically to form the core. This method creates a superior bond and a more consistent shell.

Heat Treatment: After the roll solidifies and is removed from the mold, it undergoes a rigorous heat treatment process. This involves annealing, quenching, and tempering to relieve internal stresses and develop the desired final microstructure (e.g., martensite), hardness, and toughness throughout the roll body.

Machining and Finishing: The rough cast roll is then machined on large lathes and grinders to achieve its final dimensional accuracy, precise barrel crown (or camber), and surface finish. This step is critical as it ensures the roll will run true and produce a product of consistent thickness.

Quality Control and Inspection: Every roll is subjected to non-destructive testing (NDT) like ultrasonic testing to detect internal flaws, and magnetic particle inspection to find surface cracks. Hardness is measured at multiple points across the barrel and along the length to ensure uniformity.

Understanding where each type of roll is used illustrates their strategic importance:

Roughing Stands: Here, SG iron rolls or tough adamite rolls dominate. Their job is not to create a fine finish but to reduce a large, often uneven, slab or bloom by a significant amount. They require immense strength to absorb the shock of engagement and high torque to effect the reduction.

Intermediate Stands: This is the domain of the indefinite chill double poured roll. The reduction per pass is less severe than in the roughing stand, but wear and thermal fatigue become more significant factors. The IC roll provides the perfect balance, continuing the reduction process while beginning to improve the surface quality.

Finishing Stands: This is where product quality is finalized. High-chrome iron rolls are king here. Their exceptional and consistent wear resistance ensures that the final dimensions (thickness, profile) and surface finish of the strip or bar are maintained from the first coil to the last in a production run. This consistency is vital for mill productivity and customer satisfaction.

Specialty Mills: In Steckel mills or plate mills, larger, heavier-duty versions of these rolls are used, often with specialized grades to handle the wider, heavier plate products.

The performance of cast iron rolls is directly tied to the bottom line of a steel plant. Key performance indicators (KPIs) include:

Tonnage Rolled per Millimeter of Wear: This measures the wear resistance of the roll. A higher number means the mill can produce more saleable steel between roll changes.

Consistency of Surface Finish: A roll that maintains its surface characteristics throughout its life reduces the risk of producing off-specification material that must be downgraded or scrapped.

Resistance to Spalling and Thermal Cracking: Catastrophic roll failure (spalling) can cause hours of unplanned downtime, damage to other mill equipment, and require a very expensive roll to be scrapped prematurely. Superior rolls are engineered to resist these failures.

Investing in high-quality, application-specific cast iron rolls is not an expense; it is a strategic investment in mill uptime, product quality, and overall operational efficiency.

The role of cast iron rolls is not static. Continuous innovation is driven by the steel industry’s demands for higher speeds, greater precision, and improved cost-efficiency. Key areas of development include:

Advanced Alloy Design: Metallurgists are constantly experimenting with new combinations of alloying elements like vanadium, niobium, and tungsten to create even harder carbides and more stable matrices.

Improved Manufacturing Processes: Enhancements in centrifugal casting technology, and even spin casting techniques, allow for more precise control over the shell thickness and microstructure, creating rolls with even more predictable performance.

Laser Cladding and Surface Engineering: Some manufacturers are exploring adding a final layer of ultra-wear-resistant material via laser cladding to further extend the life of the roll shell.

Digital Integration and “Smart Rolls”: While still emerging, the concept of embedding sensors within rolls to monitor temperature, stress, and wear in real-time could provide invaluable data for predictive maintenance and process optimization.

In the high-tech landscape of the modern steel industry, the cast iron roll remains an irreplaceable component. It is a testament to the enduring value of well-understood materials science, continuously refined over generations. From the rugged strength of an SG iron roughing roll to the exquisite wear resistance of a high-chrome finishing roll, these components are the silent partners in every ton of steel produced.

They may operate out of sight, deep within the mill stand, but their impact is visible in every beam that supports a building, every car body that rolls off an assembly line, and every appliance that fills a home. As the industry advances, so too will the technology behind these critical tools, ensuring that cast iron rolls continue to be the unsung heroes shaping our world, one pass at a time.