When it comes to cooking, baking, and even industrial applications, the choice of materials can significantly influence performance, durability, and results. Among the various types of rolls available today, cast iron roll and ceramic rolls are two popular options that serve different purposes. Understanding their differences, advantages, and limitations can help users make informed choices that align with their needs. This article explores the characteristics, performance, and practical considerations of cast iron rolls and ceramic rolls.

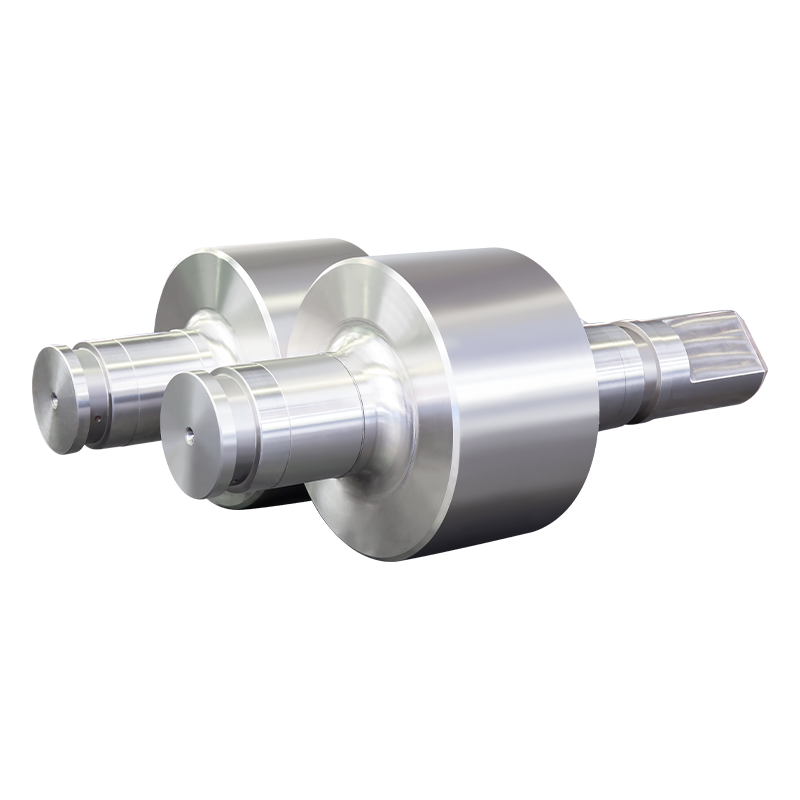

Cast iron rolls are made from molten iron that has been poured into molds and allowed to solidify. Depending on the alloy used, cast iron may contain small amounts of carbon, silicon, and other elements that enhance its strength, wear resistance, and heat retention. The dense nature of cast iron makes it exceptionally durable, which is why it has been a staple in kitchens and industry for centuries.

Ceramic rolls, on the other hand, are composed of inorganic, non-metallic materials such as alumina or zirconia. These materials are fired at extremely high temperatures, resulting in a hard, brittle, and heat-resistant surface. Ceramics are well-known for their smooth finish and ability to resist corrosion, making them an attractive alternative to metals in certain applications.

Cast iron rolls are incredibly durable and resistant to deformation under heavy use. They can handle high mechanical stress, making them ideal for tasks like rolling dough in commercial bakeries or in heavy-duty industrial processes. However, cast iron is prone to rust if not properly seasoned or coated, which means it requires routine maintenance.

Ceramic rolls are highly resistant to wear and abrasion due to their hardness. Unlike cast iron, they do not rust or corrode, making them low-maintenance. However, ceramics are brittle, meaning they can chip or crack if subjected to sudden impact or uneven pressure. This makes handling and installation important considerations.

One of the most celebrated properties of cast iron is its heat retention. Cast iron rolls absorb heat slowly but maintain it for extended periods. This property can be advantageous in baking applications, where consistent heat is needed for evenly baked products. In industrial processes that involve heating or forming materials, cast iron rolls can provide uniform temperature distribution across surfaces.

Ceramic rolls generally have lower thermal conductivity than cast iron, which means they heat up and cool down faster. This property is beneficial in applications where rapid temperature adjustments are needed or where overheating must be avoided. While ceramics can tolerate high temperatures without damage, they do not store heat as effectively as cast iron.

The surface of cast iron rolls is naturally porous, which allows it to hold oils and create a semi-nonstick effect if properly seasoned. This makes it suitable for certain food applications, such as rolling out dough or pressing items evenly. Over time, the surface may develop a patina that enhances its nonstick properties. However, unseasoned cast iron can cause food to stick and may react with acidic ingredients like tomatoes or vinegar.

Ceramic rolls feature a smooth, non-porous surface, which minimizes food adhesion and simplifies cleaning. They are chemically inert, meaning they do not react with acidic or alkaline ingredients, making them ideal for sensitive food preparation. Their non-stick surface is generally superior to that of untreated cast iron, reducing the need for oils or fats during use.

Cast iron is dense and heavy, which can be both an advantage and a disadvantage. The weight of cast iron rolls provides stability and helps maintain pressure during rolling tasks. However, their heaviness can make them cumbersome to move, install, or store, which may be a consideration in smaller kitchens or applications requiring frequent handling.

Ceramic rolls are typically lighter than cast iron, making them easier to handle and transport. This lighter weight can reduce fatigue during extended use and simplifies installation in machines or kitchen setups. However, lighter rolls may require more careful handling to maintain even pressure during rolling or forming tasks.

Cast iron rolls require regular maintenance, including seasoning, cleaning, and protection from moisture to prevent rust. With proper care, however, cast iron rolls can last decades, making them a long-term investment. Periodic re-seasoning and avoiding abrasive cleaning methods are essential to maintain their performance.

Ceramic rolls are virtually maintenance-free. They do not rust or corrode and are resistant to chemical damage. Cleaning usually involves a simple wipe or mild detergent, and there is no need for seasoning. Their longevity is mostly limited by mechanical damage, such as chipping or cracking from accidental impacts.

Generally, cast iron rolls are less expensive than ceramic rolls. The material is widely available, and the manufacturing process is well-established. While initial costs are lower, ongoing maintenance and potential surface treatments may add minor long-term expenses.

Ceramic rolls tend to be more expensive due to the specialized materials and firing processes required for production. However, their low-maintenance nature and chemical inertness can justify the higher upfront cost, especially in industrial applications or environments requiring hygiene and ease of cleaning.

Cast iron is recyclable, and many cast iron products can last for decades, reducing the need for replacement. However, improper seasoning or exposure to moisture can cause rust, which may affect hygiene in food applications.

Ceramics are chemically inert and generally safe for food contact. They do not leach metals or react with acidic ingredients. Their brittleness, however, means that broken pieces can pose hazards if not handled carefully.

Choosing between a cast iron roll and a ceramic roll largely depends on your specific needs, budget, and intended applications.

Choose a Cast Iron Roll if you prioritize durability, heat retention, and the ability to withstand heavy mechanical use. Proper maintenance will allow it to last for decades, making it a cost-effective solution over time.

Choose a Ceramic Roll if you need a low-maintenance, non-reactive, and easy-to-clean surface that performs well under chemical exposure and rapid temperature changes. Ceramics excel in precision applications but require careful handling to avoid damage.

Ultimately, both cast iron rolls and ceramic rolls have distinct strengths and limitations. Understanding these differences ensures that you select the material best suited for your cooking, baking, or industrial requirements.