In modern metalworking industries, rolling mills play a critical role in shaping and refining metal products. Among the many components of a rolling mill, roll ring is key elements that directly influence efficiency, product quality, and operational stability. Understanding how roll rings reduce friction in rolling mills is essential for engineers, technicians, and anyone involved in metal production.

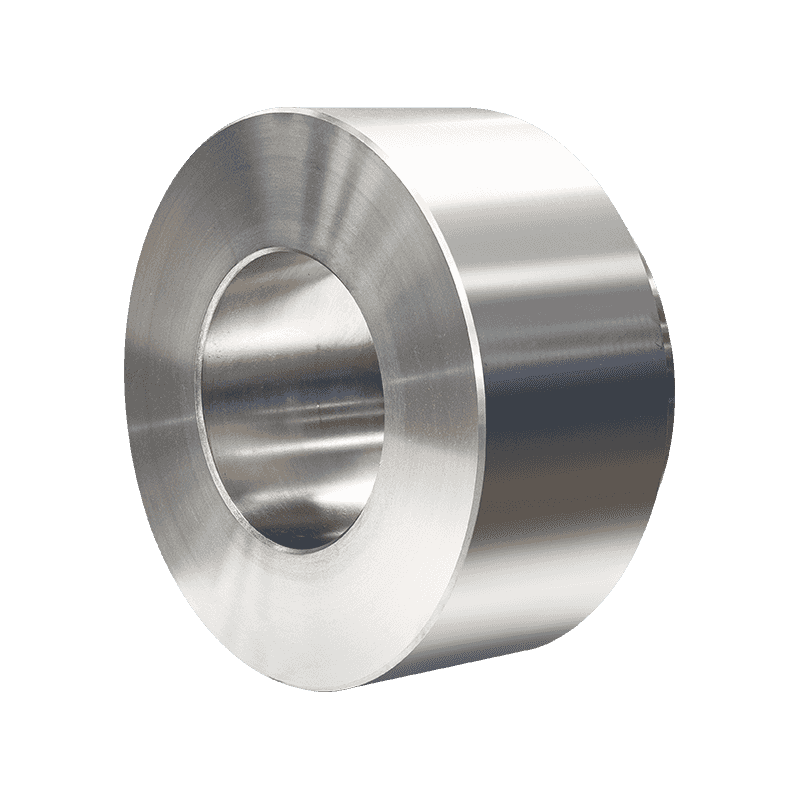

A roll ring is a cylindrical component that forms the outer shell of a roll in a rolling mill. While the roll itself rotates around a central axis, the roll ring provides the surface that comes into direct contact with the metal being processed. This makes the roll ring a critical interface between the machinery and the metal product.

Roll rings are designed to endure extreme conditions, including high pressure, high temperature, and rapid rotational speeds. The friction generated between the roll ring and the metal surface is a significant factor in rolling operations. Excessive friction can lead to wear, heat buildup, and deformation, all of which can reduce the lifespan of the roll and compromise product quality. By carefully selecting the materials, surface treatments, and design features of roll rings, engineers can significantly reduce friction and enhance rolling efficiency.

Friction in rolling mills has a dual impact. On one hand, some friction is necessary to move and shape the metal. On the other hand, excessive friction can create operational problems. High friction generates heat, which can soften the metal unevenly and increase wear on the roll surfaces. It can also cause slippage, reduce rolling efficiency, and require more energy input from the mill’s drive system.

Reducing friction is therefore a key objective in roll ring design. Lower friction results in smoother operation, less energy consumption, and improved surface quality of the rolled metal. Effective friction management also extends the service life of rolls, reducing downtime and maintenance costs.

The selection of roll ring materials is critical to controlling friction. Roll rings are generally made from highly wear-resistant and heat-resistant alloys. Common choices include alloy steels and specialized metallic composites. These materials are chosen for their ability to maintain hardness under high temperatures and to resist surface wear caused by continuous contact with hot metal.

Advanced roll rings often incorporate surface treatments or coatings that further reduce friction. For example, nitriding or chrome plating can create a hard, smooth surface that minimizes metal-to-metal contact. The smoother and harder the roll ring surface, the less friction it generates, leading to more efficient rolling and better surface finish on the final product.

The surface quality of roll rings is a major determinant of friction. Smooth, flat surfaces reduce resistance and allow the metal to flow more easily over the roll. Any irregularities, such as scratches or pits, increase friction, create localized heat, and can lead to defects in the rolled metal.

Maintaining high surface quality requires precision machining during manufacture and regular maintenance during use. Polishing, grinding, and surface inspection are standard practices to ensure that roll rings retain optimal smoothness and flatness throughout their operational life.

Beyond materials and surface treatment, the design of roll rings also influences friction. Factors such as ring geometry, thickness, and fit on the roll body determine how evenly pressure is distributed during rolling. A well-designed roll ring distributes force evenly across the contact area, minimizing localized stress and friction hotspots.

Another important consideration is thermal expansion. During rolling, both the roll and the roll ring heat up. A precise fit that accounts for thermal expansion ensures consistent contact with the metal and prevents uneven friction, which can affect product quality and accelerate wear.

Even the best-designed roll rings require maintenance to continue reducing friction effectively. Regular inspection for wear, surface damage, and misalignment is essential. Roll rings are often replaced or reconditioned before they reach critical wear levels, preventing excessive friction and potential damage to the rolling mill.

Lubrication also plays a role in managing friction. While roll rings are designed to operate under dry conditions in many processes, certain rolling applications use lubricants to further reduce surface resistance. Proper lubrication extends the life of the roll rings and enhances metal flow during rolling.

The impact of reduced friction in rolling mills extends beyond roll ring longevity. Lower friction improves energy efficiency, reduces operational costs, and allows for higher rolling speeds without compromising product quality. It also minimizes thermal stress on both the roll and the metal, contributing to consistent thickness, dimensional accuracy, and surface finish of the rolled products.

Investing in high-quality roll rings and maintaining optimal surface conditions ensures that rolling mills operate smoothly, safely, and efficiently. Engineers can achieve a balance between adequate friction for material handling and minimal friction to reduce wear and energy consumption.

Roll rings are indispensable components in rolling mills, serving as the interface between machinery and metal products. Their design, material composition, and surface quality play a crucial role in managing friction during rolling operations. By reducing friction, roll rings enhance rolling efficiency, extend equipment life, and improve the quality of finished metal products. Proper maintenance, precise manufacturing, and careful material selection are essential to maximizing the benefits of roll rings. Understanding how roll rings reduce friction helps engineers optimize rolling mill performance and maintain high standards in metal production.