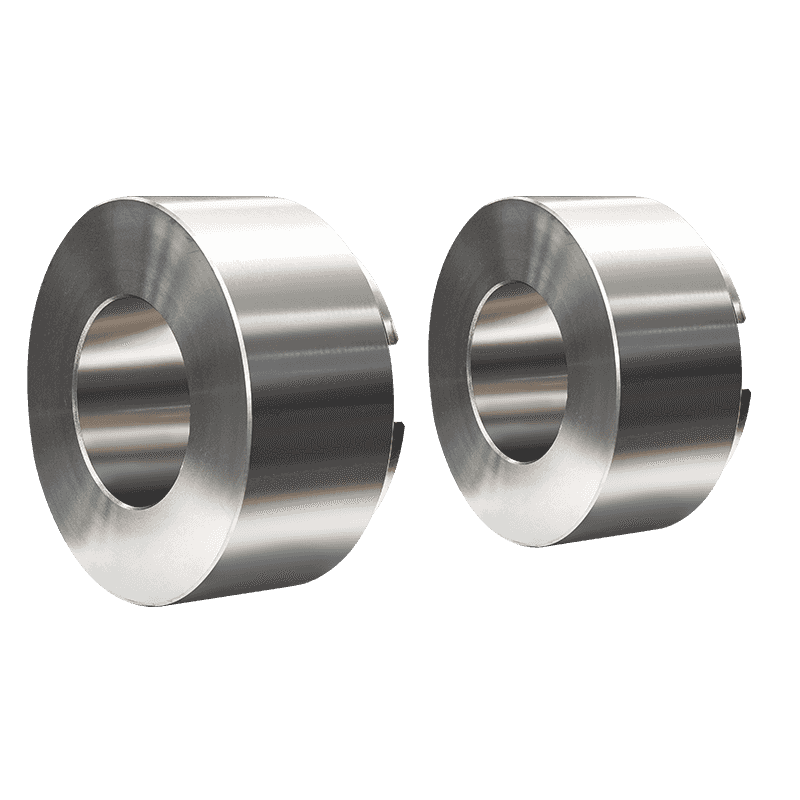

In the high-stakes world of metal processing and rolling mills, the unsung hero often comes clad in steel. Enter the cast steel roll ring—an essential yet overlooked component that defines performance, durability, and operational efficiency across countless industrial sectors.

The Backbone of Rolling Systems

A cast steel roll ring is more than just a circular block of metal. It’s the point of contact between machinery and the raw materials being shaped, pressured, and processed into final forms. Whether in hot rolling or cold rolling applications, these rings absorb immense forces, sustain harsh temperatures, and maintain dimensional integrity under constant stress. In short, they make modern manufacturing possible.

Made from specially formulated steel alloys, cast steel roll rings are engineered to withstand punishing mechanical loads and abrasive environments. Their surface hardness, internal toughness, and thermal resistance converge to form a product that doesn’t just survive under pressure—it thrives.

Material Matters

The metallurgical backbone of a roll ring lies in its composition. Cast steel provides a compelling combination of strength and ductility. Unlike other materials that crack or flake under thermal fatigue, high-quality cast steel resists spalling and deformation. Enhanced with alloying elements such as chromium, molybdenum, and nickel, the structure becomes more resilient, less prone to brittleness, and better equipped to perform in high-temperature rolling lines.

Moreover, the manufacturing process—centrifugal casting, static casting, or precision forging—impacts the final product’s uniformity and grain structure. Each method is chosen based on the operational demands, ensuring that the ring’s internal properties align seamlessly with its external expectations.

Performance That Pays Dividends

Durability is not a luxury; it’s a requirement. A substandard roll ring can disrupt production lines, generate inconsistent finishes, and escalate maintenance costs. By contrast, a well-engineered cast steel roll ring offers stability and repeatability across extended production cycles. Reduced wear rates mean fewer interruptions. Tighter tolerances translate into higher product quality.

There’s a compounding return on investment here: fewer shutdowns, less tooling replacement, and greater confidence in long-term scheduling. For manufacturers, that means greater yield and tighter control over margins.

Adaptability Across Industries

The utility of cast steel roll rings transcends sectors. They are indispensable in the steel industry, of course—but they also find roles in aluminum processing, copper rolling, and even the production of specialty alloys. Their adaptability allows them to be tailored to specific loads, speeds, and rolling conditions. In each case, the ring serves as a linchpin that quietly drives productivity.

Advanced simulation technologies and digital modeling now enable custom optimization. Engineers can predict wear patterns, simulate stress zones, and fine-tune heat treatment protocols before a single cast is poured. The result? Bespoke performance built on data-backed decisions.

Future-Facing Innovation

As manufacturing evolves, so too must its foundational components. Modern cast steel roll rings are now being integrated with smart monitoring systems—sensors embedded directly into the steel matrix to track temperature fluctuations, vibrations, and strain levels in real-time. This isn’t science fiction—it’s the new frontier of predictive maintenance and digitalized manufacturing ecosystems.

Additionally, sustainability has entered the conversation. Environmentally conscious steelmakers are exploring recycled alloy inputs and cleaner casting processes to reduce the ecological footprint of each roll ring. Efficiency and responsibility are no longer mutually exclusive.

The cast steel roll ring may not capture headlines, but its role is monumental. It’s a workhorse forged in fire, engineered for resilience, and optimized for precision. In the intricate ballet of heavy industry, it stands as both guardian and guide—ensuring that every roll, press, and pass delivers to specification.