In the demanding world of metal rolling, where immense pressure, friction, and extreme temperatures are the norm, the choice of roll material is paramount to operational efficiency, product quality, and overall profitability. Among the various options available, High Speed Steel (HSS) rolls have emerged as a transformative technology, particularly in modern hot and cold rolling mills. This guide delves into what makes HSS work rolls unique, their key benefits, primary applications, and best practices for their use and maintenance.

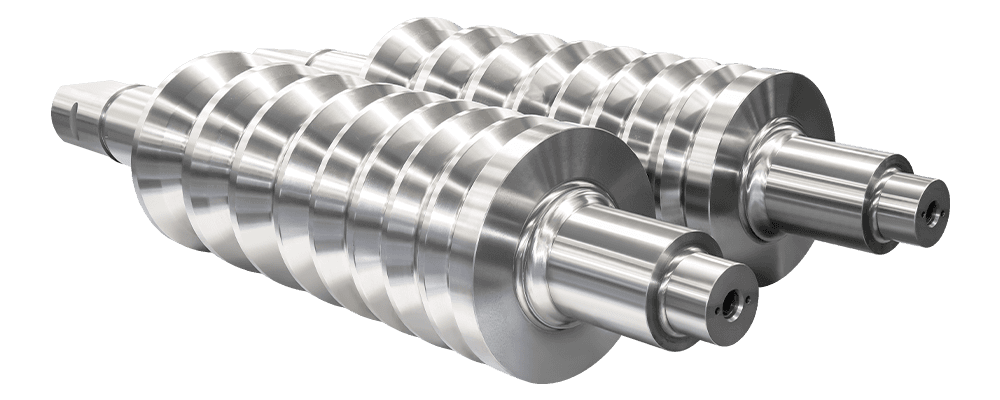

At their core, High Speed Steel rolls are not made from conventional steel or iron used for traditional rolls. Instead, they are composite rolls where the outer working layer is a sophisticated alloy characterized by a high volume of hard, wear-resistant carbides (primarily vanadium, tungsten, molybdenum, and chromium carbides) embedded in a tough steel matrix.

This microstructure is achieved through advanced metallurgical processes like centrifugal casting or electro-slag melting and is finely tuned through precise heat treatment. The result is a roll sleeve with exceptional properties that directly address the limitations of older roll materials like high chromium iron (HSS) or indefinite chill (IC) rolls.

The unique composition of HSS rolls grants them a set of performance advantages that translate into tangible benefits for rolling mills.

Superior Wear Resistance: This is the most celebrated benefit. The high volume of hard carbides in the HSS matrix drastically reduces roll wear. This leads to a much more stable roll profile over extended campaign lengths. Mills can run longer between roll changes, directly increasing productivity and reducing downtime.

Consistent Surface Quality: Because the roll surface deteriorates much more slowly, the surface finish imparted on the strip remains consistent from the beginning to the end of a campaign. This is critical for producing high-quality sheet metal, strip, and bar products with minimal surface defects like orange peel or fire cracking, which can be an issue with other roll types.

Enhanced Resistance to Thermal Cracking (Fire Cracking): The hot rolling process subjects rolls to cyclic heating and cooling, leading to thermal fatigue. HSS alloys have a higher resistance to this phenomenon. The carbides help stabilize the microstructure against the thermal shocks encountered when contacting the hot slab and then the cooling water, resulting in a finer and more controlled network of micro-cracks, if any appear at all.

High Hardness at Elevated Temperatures (Red Hardness): Unlike other materials that soften with heat, HSS retains its hardness and strength even at the high temperatures experienced during hot rolling. This ensures the roll maintains its shape and resistance to deformation under load, contributing to better gauge and shape control of the final product.

HSS rolls are not a one-size-fits-all solution, but they excel in specific stands and processes:

It’s important to note that the exceptional hardness of HSS rolls can make them less suitable for roughing stands, where toughness and resistance to impact are more critical than extreme wear resistance.

To maximize the investment in HSS rolls and ensure their longevity, proper handling and maintenance are non-negotiable.

The decision to switch to or incorporate High Speed Steel rolls is an investment in operational excellence. While the initial cost per roll is higher than traditional options, the Total Cost of Ownership (TCO) is often lower. This is due to:

For mill managers and engineers focused on improving strip quality, increasing productivity, and controlling long-term costs, understanding and leveraging the capabilities of High Speed Steel rolls is no longer an option—it’s a necessity for remaining competitive in today’s market. By selecting the right grade for your specific application and adhering to strict maintenance protocols, HSS rolls can deliver unparalleled performance and a strong return on investment.