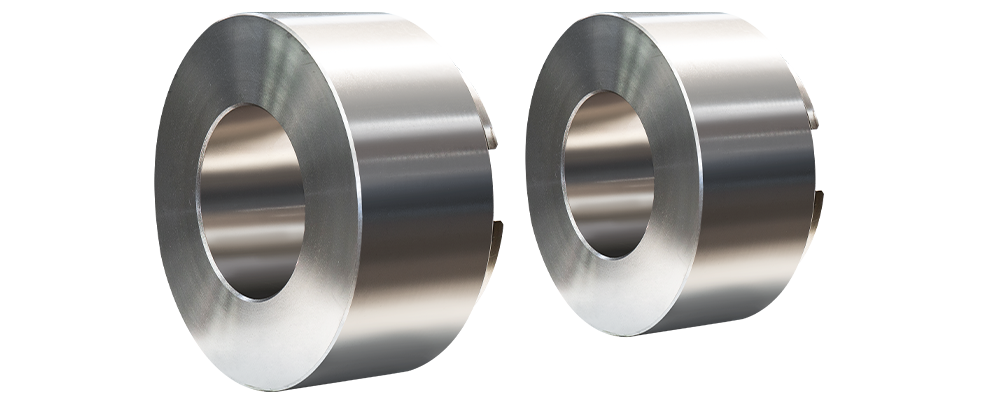

Roll ring, also known as rotary joints or slip rings, are crucial components in rotating machinery, enabling the transmission of power, signals, or fluids between stationary and moving parts. They are widely used in industries such as manufacturing, wind energy, robotics, and medical equipment. This article explores the function, types, and key considerations for selecting the right roll ring for your application.

A roll ring is an electromechanical device that allows the transfer of electrical signals, power, or data from a stationary structure to a rotating one. Unlike traditional wiring, which can tangle or wear out due to continuous rotation, roll rings provide a reliable and maintenance-free solution for rotating systems.

Roll rings come in various designs, each suited for specific applications. Below is a comparison of common types:

| Type | Key Features | Common Applications |

| Electrical | Transmits power and signals | Wind turbines, robotics, packaging machines |

| Fluid | Allows hydraulic/pneumatic fluid transfer | Industrial machinery, medical imaging systems |

| Hybrid | Combines electrical and fluid transmission | Heavy machinery, aerospace systems |

| Fiber Optic | High-speed data transfer with low loss | Military, telecommunications, radar systems |

These are the most common type, used in applications requiring continuous power and signal transmission. Examples include:

Designed for systems requiring liquid or gas transfer, such as:

These combine electrical and fluid channels, making them ideal for complex machinery like:

Used in high-bandwidth applications where electrical interference is a concern, such as:

Selecting the appropriate roll ring depends on several factors:

Roll rings play a vital role in modern machinery, ensuring seamless power, signal, and fluid transmission in rotating systems. By understanding the different types and selection criteria, engineers and technicians can optimize performance while minimizing maintenance. Whether for industrial automation, renewable energy, or advanced robotics, choosing the right roll ring enhances efficiency and reliability.