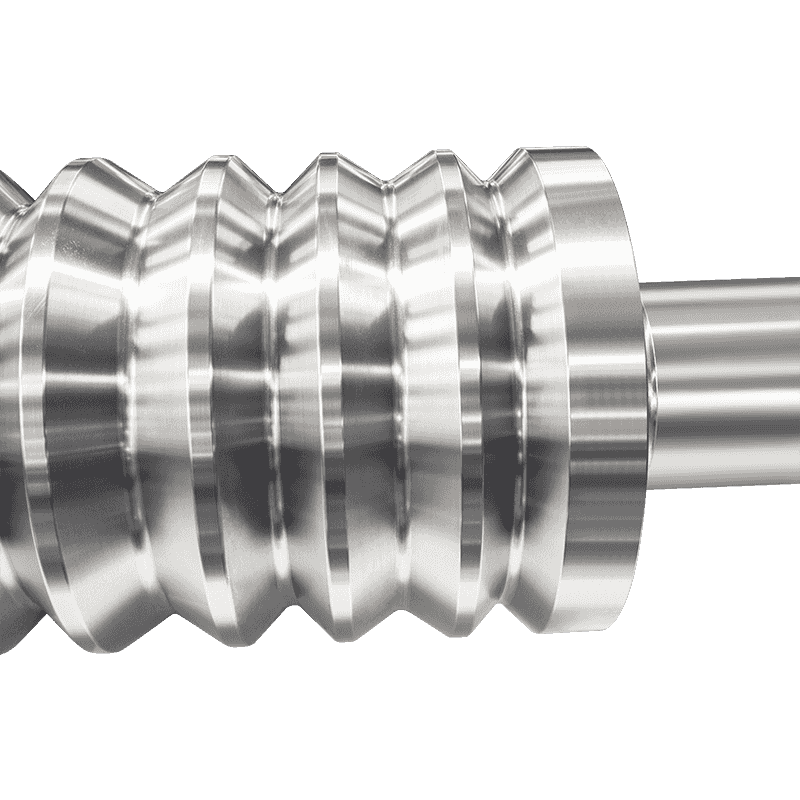

High speed steel rolls are widely used in modern industrial rolling applications due to their high hardness, wear resistance, and ability to withstand elevated temperatures. Despite these intrinsic properties, surface treatment technologies are often applied to HSS rolls to further enhance performance, extend service life, and maintain precision under challenging operating conditions.

HSS rolls operate under intense mechanical and thermal stresses during rolling processes. The primary challenges include wear, oxidation, thermal fatigue, and surface deformation. While HSS itself provides considerable resistance to these factors, the surface layer often experiences accelerated deterioration, affecting dimensional accuracy and surface quality of rolled products.

Surface treatment technologies are designed to:

The choice of surface treatment depends on the rolling material, process conditions, and specific operational requirements.

Grinding and polishing are often the first step in preparing the surface of HSS rolls. These processes are primarily mechanical and focus on improving surface smoothness and geometric accuracy.

Regular maintenance using grinding and polishing prolongs roll life and ensures consistent product quality.

Nitriding is a thermochemical treatment in which nitrogen atoms diffuse into the steel surface, forming hard nitrides. The process is carried out at moderate temperatures, typically between 500 and 550 degrees Celsius, avoiding distortion of the roll.

Benefits of nitriding include:

Nitrided HSS rolls are particularly suitable for high speed rolling of stainless steel and other tough materials where surface wear is significant.

Carburizing introduces carbon into the surface layer of the steel, creating a hardened outer shell with a tougher core. Carbonitriding is similar but adds both carbon and nitrogen, enhancing surface hardness while maintaining ductility.

Advantages of carburizing and carbonitriding:

These treatments require careful temperature and time control to prevent distortion and cracking.

Chrome plating involves electrochemically depositing a layer of chromium onto the HSS roll surface. This creates a hard, wear-resistant layer with excellent corrosion resistance.

Benefits of chrome plating:

Chrome plating is commonly applied to rolls used in the paper, steel, and aluminum industries. However, it requires precise control to avoid peeling or uneven coating thickness.

Physical vapor deposition (PVD) coatings, such as titanium nitride (TiN), titanium carbonitride (TiCN), and chromium nitride (CrN), are increasingly used for HSS rolls requiring extreme wear resistance.

Key benefits of PVD coatings:

PVD coatings are suitable for precision rolling and high speed applications where both surface hardness and dimensional accuracy are critical.

Shot peening is a mechanical surface treatment where the roll surface is bombarded with small spherical media. This introduces compressive residual stress on the surface, enhancing fatigue resistance and reducing crack propagation.

Advantages of shot peening:

Shot peening is often combined with other treatments, such as nitriding or PVD coatings, to maximize roll performance.

Laser surface hardening uses a high-energy laser beam to selectively heat the surface of the roll, followed by rapid self-quenching. This produces a hardened layer with minimal thermal distortion.

Benefits include:

Laser surface hardening is particularly useful for rolls requiring specific hardness profiles along their length or circumference.

Nickel electroplating provides corrosion protection and moderate wear resistance. It is sometimes combined with chromium plating for enhanced performance.

Advantages of nickel plating:

This treatment is often used for rolls operating in chemically aggressive environments where wear is moderate.

Selecting the appropriate surface treatment for HSS rolls depends on several factors:

Even with advanced surface treatments, HSS rolls require careful monitoring and maintenance:

Proper maintenance ensures that the benefits of surface treatment are fully realized throughout the roll’s service life.

Surface treatment technologies are essential for enhancing the performance and durability of high speed steel rolls. Common techniques such as grinding, nitriding, carburizing, chrome plating, PVD coatings, shot peening, laser hardening, and electroplating provide significant improvements in wear resistance, hardness, corrosion resistance, and fatigue life. Selecting the appropriate treatment requires careful consideration of rolling materials, operational conditions, and desired service life. When combined with regular maintenance and monitoring, surface treatments ensure that HSS rolls maintain high performance, reliability, and precision, supporting efficient and consistent industrial production.