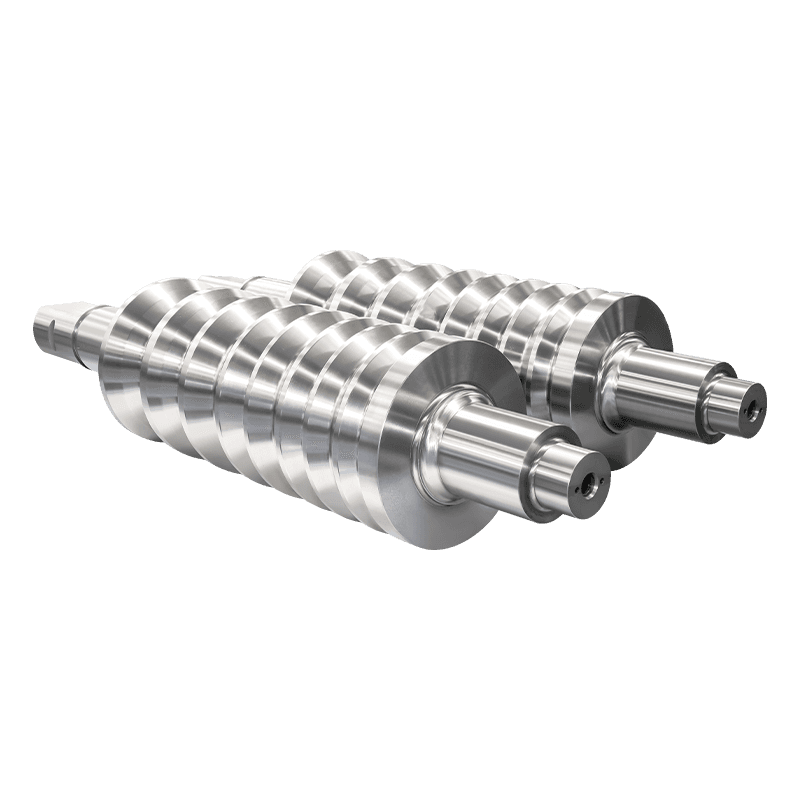

In the high-stakes world of metal production, the rolling mill is the heart of the operation. It’s where raw slabs, blooms, or billets are transformed into precise sheets, plates, bars, and structural shapes under immense pressure and heat. At the core of this process are the rolls themselves—massive, precisely engineered cylinders that bear the incredible forces required to shape metal.

When a roll fails, the consequences are severe. Production grinds to a halt, leading to costly downtime. The roll itself, a significant capital investment, may need expensive repair or be scrapped entirely. In worst-case scenarios, a catastrophic failure can damage other mill equipment and even pose safety risks. The most common and critical form of roll failure is cracking.

Understanding what causes rolling mill roll cracking and, more importantly, how to prevent it, is fundamental to achieving operational efficiency, product quality, and mill safety. This article delves into the root causes of roll failure and outlines a proactive strategy for prevention.

Before we examine the causes of cracking, it’s crucial to understand that not all rolls are the same. They are subject to different operating conditions based on their position and function:

Work Rolls: These are the rolls that directly contact the hot or cold metal product. They are typically smaller in diameter and are subjected to extreme thermal cycling and wear.

Backup Rolls: These larger, robust rolls support the work rolls, providing the necessary rigidity to prevent bending under high rolling forces. They primarily face mechanical stresses.

Intermediate Rolls: Used in some mill configurations (like 6-high mills), these rolls sit between the work and backup rolls.

Each roll type experiences a complex combination of stresses that, if not managed, lead to cracking:

Mechanical Stress: The tremendous rolling force, shear, and bending moments applied during each pass.

Thermal Stress: The intense heat from the hot metal product (in hot rolling) or the heat generated by deformation (in cold rolling) causes the roll surface to expand rapidly. The core of the roll remains cooler, creating internal stress.

Thermal Cycling: The repeated heating during rolling and cooling from lubrication or water sprays causes the roll surface to constantly expand and contract, leading to thermal fatigue.

Wear and Friction: Abrasive wear from the product and friction gradually degrade the roll surface.

Roll cracking is rarely due to a single factor. It is almost always the result of the interplay between several of the following causes.

This is the most common cause of fine, network-like surface cracking, often called “heat checking” or “crazing.”

The Mechanism: During a rolling pass, the work roll surface can exceed 500°C (932°F) in a matter of seconds. This causes the surface layer to expand. As the roll rotates away from the product, it is cooled by emulsion, water, or air, causing the surface to contract. This relentless cycle of expansion and contraction induces cyclic thermal stress.

The Result: Over time, these stresses exceed the fatigue limit of the roll material. Microscopic cracks initiate on the surface and gradually propagate inward, creating a characteristic spider-web pattern. While shallow heat checks can be managed through grinding, deep ones can be initiation points for more severe failures.

This refers to cracking caused by the cyclic mechanical loads of the rolling process.

The Mechanism: Each time a roll passes through the roll bite (the point of contact with the metal), it is subjected to bending and shear stresses. The amplitude of these stresses fluctuates with changes in rolling force, strip width, and thickness.

The Result: Similar to a paperclip being bent back and forth, the roll material eventually succumbs to fatigue. Cracks typically initiate at stress concentrators—like pre-existing micro-cracks from heat checking, grinding marks, or material inclusions—and propagate perpendicular to the direction of the highest stress, often leading to spalling or complete fracture.

Sudden, catastrophic roll failures are frequently traced back to an operational incident.

Cobbles: A cobble, where the product fails to exit the mill stand correctly and becomes wrapped around a roll, is a primary culprit. The immense, uneven forces and sudden thermal shock can instantly create major cracks.

Slabs: Accidentally rolling a slab that is outside the mill’s designed capacity (e.g., too thick, too hard, or too wide) can create forces that exceed the roll’s ultimate tensile strength.

Improper Roll Changing: Mishandling rolls during installation or storage can cause impact damage (nicks, dings) that act as potent stress concentrators.

The regrinding process is essential for restoring roll profile and removing surface defects. However, poor grinding practices are a major contributor to premature roll failure.

Grinding Burns: Excessive grinding pressure or inadequate coolant can overheat the roll surface, altering its metallurgical structure (tempering) and creating tensile stresses that lead to grinding checks (cracks).

Insufficient Removal: Failure to grind deep enough to remove all existing thermal and mechanical cracks means new cracks will quickly propagate from the old crack roots.

Poor Surface Finish: Rough grinding marks or sharp transitions in the roll profile create notches that concentrate stress.

While rare with reputable roll manufacturers, inherent flaws in the roll can be the root cause.

Inclusions: Non-metallic impurities (e.g., slag) within the roll material are weak points where cracks can easily start.

Microstructural Irregularities: Improper heat treatment during manufacturing can lead to inconsistent hardness, brittleness, or residual stresses within the roll.

Cast vs. Forged Rolls: Different manufacturing processes and material grades (e.g., High Chromium Iron, Indefinite Chill, Tungsten Carbide) have varying resistance to thermal shock, wear, and fatigue. Using the wrong roll grade for a specific application accelerates failure.

The cooling system is not just for controlling the temperature of the product; it’s critical for protecting the rolls.

Inadequate Flow or Pressure: If nozzles are clogged, misaligned, or undersized, the roll will not be cooled evenly. This leads to hot spots, excessive thermal crown (bulging in the center), and accelerated thermal fatigue.

Incorrect Coolant Mixture: The wrong concentration or type of rolling oil or emulsion can reduce its heat transfer efficiency and lubricity, increasing both thermal and mechanical stress on the rolls.

Prevention is not about a single silver bullet but a disciplined, systematic approach to roll management.

Optimize Mill Operations and Control:

Prevent Cobbles: Implement robust process control systems to monitor tension, speed, and temperature to minimize the risk of cobbles. Ensure operators are well-trained in emergency procedures.

Avoid Overloading: Strictly adhere to the mill’s rolling schedules and designed limits for product grade, width, and reduction per pass.

Ensure Correct Roll Alignment: Misaligned rolls cause uneven load distribution, leading to localized stress peaks and accelerated wear.

Master Thermal Management:

Implement Roll Cooling Best Practices: Establish a rigorous preventive maintenance schedule for the cooling system. Regularly inspect, clean, and calibrate all nozzles to ensure uniform coverage across the entire roll barrel length.

Use Roll Heaters: For backup rolls, pre-heating before placing them into service prevents thermal shock from the initial contact with the warm work rolls.

Consider Progressive Cooling: After a long campaign, allow rolls to cool down gradually in a controlled environment rather than exposing them to rapid ambient cooling.

Elevate Roll Grinding and Inspection Standards:

Adopt a “Zero-Crack” Grinding Policy: The goal of every grind should be to remove all evidence of previous cracking. Use non-destructive testing (NDT) methods like dy penetrant inspection (DPI) or ultrasonic testing to verify the roll is crack-free before being returned to service.

Prevent Grinding Burns: Use proper grinding techniques with ample coolant and appropriate feed rates. Monitor the process to avoid generating excessive heat.

Maintain Precise Profile and Finish: Grind to the specified crown and surface finish to ensure even load distribution and eliminate stress concentrators.

Implement a Rigorous Roll Management Program:

Track Roll History: Maintain detailed records for each roll, including total tonnage rolled, number of regrinds, downtime reasons, and all NDT inspection reports. This data is invaluable for identifying trends and predicting end-of-life.

Handle with Care: Use proper rigging and storage equipment to prevent impact damage. A small nick can cost thousands in regrinding depth or lead to a catastrophic failure.

Select the Right Roll for the Job: Work closely with your roll supplier to ensure the roll material grade (e.g., its resistance to thermal shock or wear) is perfectly matched to the specific stand position and product being rolled.

Invest in Training and Culture:

Ultimately, the best practices are only as good as the people implementing them. Invest in comprehensive training for mill operators, roll grinders, and maintenance personnel. Foster a culture where everyone understands that careful roll management is directly tied to the mill’s productivity, cost-effectiveness, and safety.

Rolling mill roll cracking is an inevitable result of the extreme conditions inherent to metal forming. However, its frequency and severity are entirely within an operation’s control. By moving from a reactive mindset (“we’ll grind it out”) to a proactive, data-driven strategy focused on root cause analysis, mills can significantly extend roll life, reduce downtime, and enhance safety.

The causes—thermal fatigue, mechanical overload, improper maintenance—are well-understood. The solutions—meticulous grinding, optimized cooling, careful operation, and thorough inspection—require discipline and investment. That investment pays for itself many times over in the form of consistent production, reduced roll consumption, and the avoidance of a single, disastrous catastrophic roll failure. Protecting your rolls is fundamentally about protecting your bottom line.