Cast Steel Roll is crucial components in many industrial processes, particularly in steel mills, rolling mills, and heavy machinery applications. Their performance directly influences product quality, production efficiency, and equipment longevity. As with any high-value industrial component, proper maintenance is essential not only to extend service life but also to ensure consistent operation and safety.

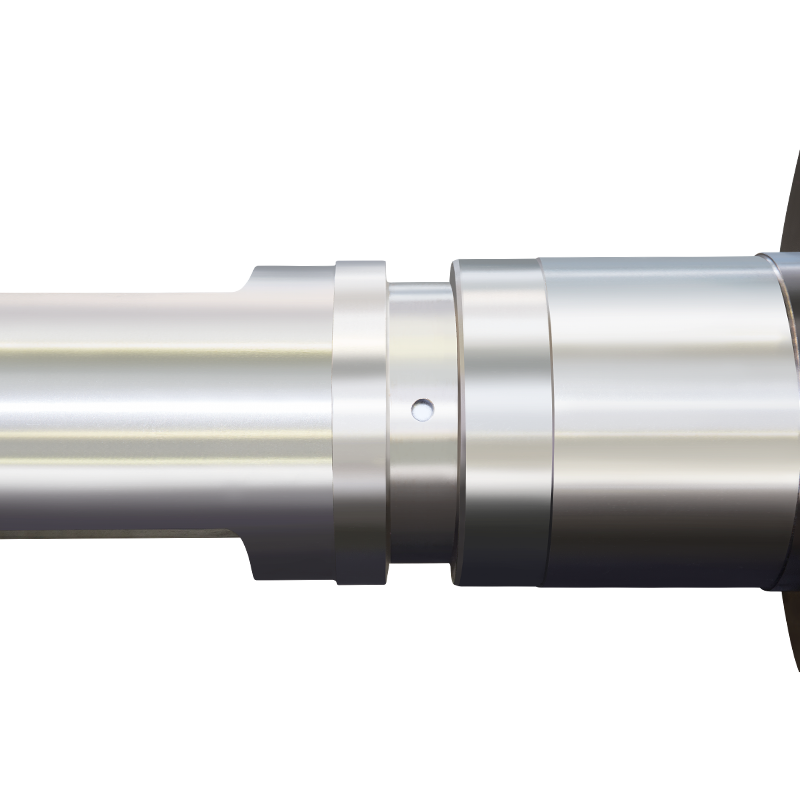

Before discussing maintenance practices, it’s important to understand what Cast Steel Rolls are and how they function. A Cast Steel Roll is a cylindrical component made from alloyed or carbon steel, often heat-treated to achieve the necessary hardness and strength for rolling applications. These rolls are responsible for shaping, compressing, or flattening materials—most commonly metals—under high pressure.

Depending on the specific application, Cast Steel Rolls can experience extreme mechanical stress, thermal cycling, and surface wear. The surface of the roll must remain smooth and precise to ensure the desired product finish, while the core must maintain structural integrity to withstand load forces. Given these demanding conditions, even minor surface irregularities or fatigue can lead to significant production losses. This is why consistent and methodical maintenance is a key factor in operational success.

Routine inspection is the cornerstone of Cast Steel Roll maintenance. The goal is to detect signs of wear, cracking, or surface degradation before they escalate into costly failures.

Key inspection steps include:

Setting a regular inspection schedule—based on production hours, rolling tonnage, or thermal cycles—helps ensure that potential issues are addressed proactively rather than reactively.

Cleanliness plays a significant role in maintaining the condition of a Cast Steel Roll. Residue, scale, and foreign particles can lead to surface damage and uneven wear.

Recommended cleaning practices:

Keeping the roll surface clean ensures uniform contact with the processed material and prolongs both the roll’s lifespan and the quality of the final product.

Proper lubrication and cooling are critical to reducing friction, heat generation, and wear during operation.

Lubrication guidelines:

Cooling practices:

Balanced lubrication and cooling practices contribute significantly to the stable performance of Cast Steel Rolls and reduce the risk of premature surface damage.

Improper handling is one of the most common causes of premature roll damage. Cast Steel Rolls are heavy and sensitive precision components that require careful treatment during transportation, installation, and storage.

Handling recommendations:

Storage guidelines:

These precautions help maintain the structural integrity and readiness of Cast Steel Rolls for future use.

Even with careful maintenance, every Cast Steel Roll will eventually exhibit wear that affects its performance. Reconditioning extends the roll’s service life and ensures optimal operation.

Common reconditioning processes include:

Partnering with experienced service providers for reconditioning ensures that the roll is restored to its intended performance specifications.

An organized maintenance record is essential for tracking the condition and performance of Cast Steel Rolls over time. By documenting inspections, repairs, and operational data, maintenance teams can identify patterns and schedule interventions more effectively.

Best practices for recordkeeping:

Predictive maintenance technologies, such as vibration analysis and thermal imaging, are becoming increasingly valuable. These tools can detect early warning signs of imbalance, bearing wear, or overheating—allowing maintenance teams to act before failure occurs.

Maintaining a Cast Steel Roll involves much more than occasional inspection—it requires a disciplined approach that integrates cleaning, lubrication, careful handling, and timely reconditioning. Each of these practices contributes to extending the roll’s lifespan, reducing operational downtime, and ensuring consistent product quality.

In essence, a well-maintained Cast Steel Roll represents not only a cost-saving asset but also a cornerstone of reliable production. By following recommended maintenance practices and establishing a proactive monitoring system, industries can significantly enhance the performance and longevity of their rolling equipment, ultimately leading to safer and more efficient operations.