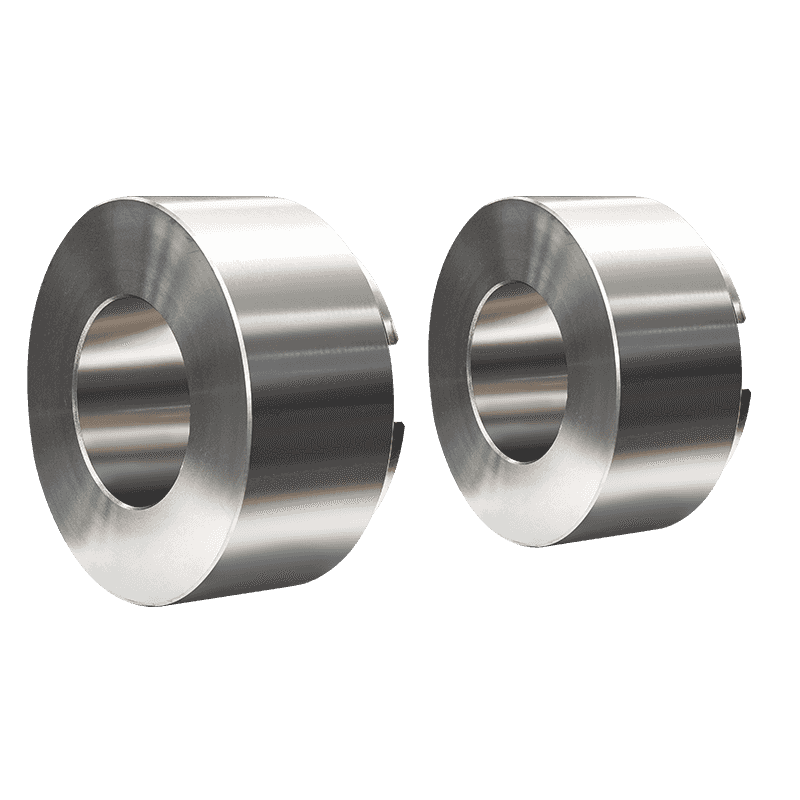

Cast steel roll ring is critical components in the steel, nonferrous metal, and manufacturing industries. Their reliability directly affects the efficiency, precision, and safety of rolling processes used in producing sheets, bars, and other metal products. Because they operate under extreme thermal and mechanical stresses, quality assurance is not optional—it is essential. The testing methods used to verify the quality of cast steel roll rings ensure that each ring can withstand demanding service conditions, maintain dimensional accuracy, and deliver long-term performance.

Quality control begins with the simplest yet most vital step—visual and dimensional inspection. This method helps detect surface defects and verify the ring’s physical dimensions against design specifications.

Visual inspection involves a detailed examination of the cast steel roll ring’s surface. Trained inspectors look for cracks, blowholes, shrinkage cavities, laps, inclusions, or other surface irregularities. Surface defects can be caused by improper casting, uneven cooling, or contamination in the molten metal. Early identification helps prevent costly downstream processing of defective products.

Dimensional inspection ensures that the roll ring meets the exact measurements specified by engineering drawings. Using precision tools such as calipers, coordinate measuring machines (CMM), and laser scanners, inspectors verify the outer diameter, bore size, width, and profile shape. Dimensional accuracy is crucial for ensuring the ring fits correctly into the rolling mill and operates smoothly.

Chemical composition plays a central role in determining the mechanical performance of cast steel roll rings. Elements such as carbon, chromium, molybdenum, and nickel are carefully controlled to achieve the desired hardness, wear resistance, and toughness.

Testing methods like optical emission spectroscopy (OES) and X-ray fluorescence (XRF) are used to verify that the alloy composition meets required specifications. OES involves exciting atoms within the sample using an electrical discharge; the emitted light is analyzed to determine the concentrations of each element. XRF, on the other hand, detects the characteristic X-rays emitted when the sample is exposed to a high-energy beam.

Accurate chemical analysis ensures consistency in the metallurgical properties of each roll ring batch. Any deviation in composition—such as excessive sulfur or phosphorus—can weaken the material, making it more prone to cracking or premature wear.

After confirming the chemical composition, the next stage focuses on verifying mechanical strength and durability. Cast steel roll rings must endure enormous stresses during operation, so mechanical property tests assess their ability to resist deformation and fracture.

Hardness testing is one of the most common and critical mechanical evaluations. Techniques like Brinell, Rockwell, or Vickers hardness tests are applied depending on the size and surface condition of the ring.

Hardness distribution is often measured across the cross-section to assess the uniformity of the heat treatment process. Uneven hardness can lead to localized wear or cracking during service.

Tensile testing determines how the material behaves under axial stretching. A sample cut from the same cast batch is tested to find its yield strength, ultimate tensile strength, and elongation. These values indicate the ductility and resistance to failure under load.

For components subjected to sudden stress changes, Charpy V-notch impact testing measures toughness at various temperatures. The test reveals how well a cast steel roll ring can absorb energy without fracturing—a vital property for rolls operating in environments with fluctuating thermal and mechanical conditions.

While mechanical tests require cutting or machining samples, non-destructive testing (NDT) allows engineers to examine the integrity of the cast steel roll ring without damaging it. NDT methods reveal hidden defects, cracks, or inclusions that could compromise performance.

Ultrasonic testing is widely used to detect internal flaws. High-frequency sound waves are transmitted into the roll ring, and the reflected signals are analyzed. Discontinuities such as voids or cracks reflect the waves differently, helping technicians identify their size and location.

UT is highly effective for detecting subsurface defects that visual inspection cannot find.

Magnetic particle testing detects surface and near-surface cracks in ferromagnetic materials. The roll ring is magnetized, and fine iron particles are applied. These particles gather at discontinuities, making defects visible under light.

MT is particularly useful for detecting small surface cracks around the edges and bore areas of cast steel roll rings.

For non-ferromagnetic or polished surfaces, dye penetrant testing is used. A colored or fluorescent dye is applied to the surface, seeping into any cracks. After wiping the excess dye, a developer draws the trapped dye back to the surface, revealing defects under visible or UV light.

Radiographic testing uses X-rays or gamma rays to examine the internal structure of the roll ring. The resulting image displays variations in density caused by defects like porosity or inclusions. RT provides a permanent record of internal integrity and is often applied to critical roll rings used in high-performance mills.

Microstructure analysis reveals the internal arrangement of grains, phases, and carbides that determine mechanical behavior. Using optical microscopy and scanning electron microscopy (SEM), metallurgists examine polished and etched cross-sections of the roll ring.

Key observations include:

Microstructural consistency across the section ensures that the ring will perform uniformly in service, preventing localized failures or uneven wear patterns.

Residual stresses develop in cast steel roll rings during cooling and heat treatment. If uncontrolled, these stresses can cause cracking or distortion. Residual stress measurement using X-ray diffraction or ultrasonic velocity techniques helps verify that the stresses are within acceptable limits.

Ultrasonic velocity testing can also be used to evaluate elastic modulus and detect any internal inconsistencies in density or soundness. These measurements provide a quick, non-destructive indication of overall quality and structural uniformity.

In service, roll rings face cyclic heating and cooling, leading to thermal fatigue. Laboratory thermal cycling tests simulate these conditions by repeatedly heating and cooling test samples. The number of cycles a material endures before cracking indicates its resistance to thermal fatigue.

Wear testing, often performed using pin-on-disc or rolling-sliding simulation equipment, evaluates how the surface resists abrasion under frictional contact. These tests are essential for predicting real-world performance, especially for rolls used in hot strip and bar mills.

To ensure even wear and proper maintenance, ultrasonic thickness gauges are used to measure wall thickness at multiple points. This helps detect any irregularities caused by casting or machining.

Surface profile measurement using laser scanners or stylus-based instruments ensures that the working surface maintains the correct contour and finish. Proper surface geometry affects how evenly the roll distributes pressure on metal sheets during rolling.

For rolls with hardened working layers, verifying the depth of hardness is crucial. Through cross-sectional hardness profiling, inspectors ensure that the hardened layer extends deep enough to provide long-term wear resistance.

This test also confirms that the transition between the hardened surface and softer core remains gradual, preventing delamination or surface cracking.

Before installation, dynamic balancing ensures that the cast steel roll ring operates smoothly at high rotational speeds. Even minor imbalances can cause vibration, leading to uneven rolling and bearing wear.

Dynamic balancing machines measure imbalance and adjust it by removing or adding material, ensuring stable rotation during operation.

Every test result—from chemical analysis to mechanical testing—is documented in a quality assurance report. This report provides traceability for each roll ring, linking its production batch, material composition, and test results.

Traceability allows manufacturers and end-users to identify the root cause of any performance issues and verify compliance with industry standards such as ISO, ASTM, or EN specifications.

The quality assurance of cast steel roll rings depends on a comprehensive combination of destructive and non-destructive testing methods. Each test—whether it measures hardness, examines microstructure, or detects hidden flaws—contributes to ensuring that the roll ring performs reliably under extreme operational conditions.

From initial visual inspection to advanced radiographic imaging and microstructural analysis, every step in testing strengthens the reliability of these critical components. High-quality cast steel roll rings not only enhance rolling efficiency and product quality but also reduce maintenance costs and operational downtime.

Ultimately, quality assurance is not just about passing tests—it’s about instilling confidence that each cast steel roll ring can endure the heat, pressure, and precision demands of modern metalworking industries.