In the thunderous heart of a rolling mill, where red-hot steel is shaped and transformed, every component has a purpose. Among the most critical are the work rolls—the massive cylinders that directly contact and deform the metal. A keen observer will notice a distinct pattern: the rugged, often heavily scarred rolls in the initial roughing stands differ from the sleek, polished rolls in the final finishing stands. This is not by accident. The prevalent use of cast iron roll in roughing stands, as opposed to finishing stands, is a deliberate choice rooted in fundamental material properties, economic efficiency, and the specific demands of each stage of the rolling process.

A rolling mill is a series of stands, each containing a pair of work rolls, that progressively reduce the thickness of a metal slab.

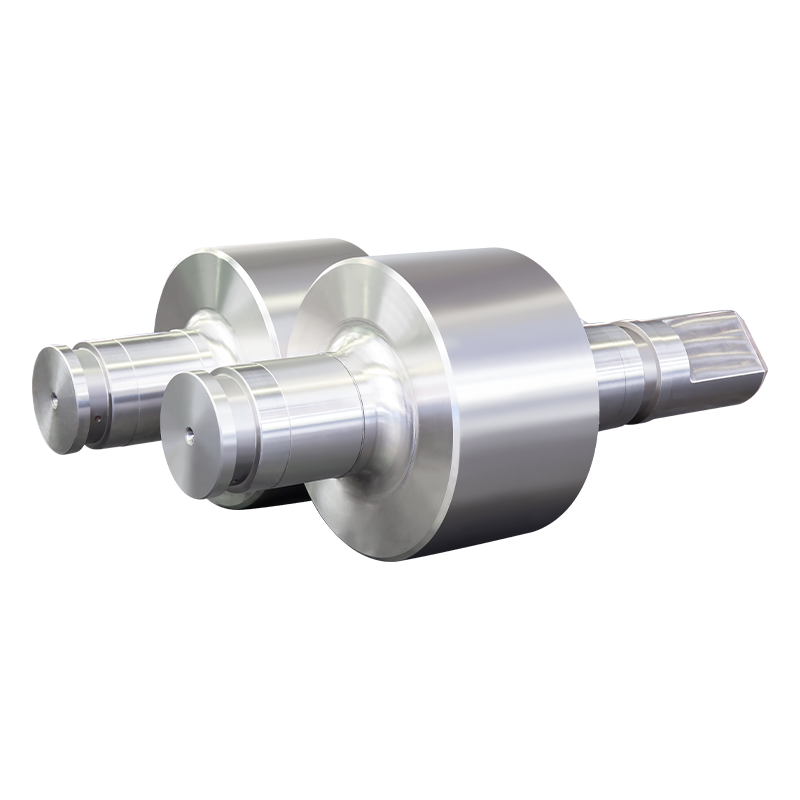

The Roughing Stands: These are the first stands the material encounters. Their primary job is to break down a large, often rectangular, ingot or slab into a more manageable bar or strip. This stage involves massive reductions in thickness, high mechanical loads, and extreme temperatures. The goal here is not a perfect surface finish, but rather efficient and powerful deformation to establish the basic profile and dimensions.

The Finishing Stands: Located downstream, these stands receive the pre-formed bar from the roughing mill. Their role is precision. They apply lighter, more controlled reductions to achieve the final dimensional accuracy, mechanical properties, and, crucially, a high-quality surface finish on the product.

This division of labor dictates very different requirements for the rolls used in each section.

Cast iron, particularly grades with nodular graphite, is the material of choice for roughing stands for several key reasons related to its inherent properties.

1. Superior Resistance to Thermal Shock and Cracking

Roughing stands operate in a thermally brutal environment. A water-cooled, room-temperature roll continuously bites into metal glowing at over 1,000°C. This creates intense, localized heating on the roll surface, followed by rapid cooling from the water sprays. This cyclic heating and cooling generates enormous thermal stresses.

Cast iron excels here. Its high carbon content, present largely as free graphite flakes or nodules, gives it two advantages:

The graphite acts as a network of internal “cracks” or voids. This structure inherently disrupts the path of a propagating thermal crack, blunting its tip and preventing it from spreading deeply enough to cause a catastrophic roll failure.

Graphite improves thermal conductivity. It helps dissipate some of the intense surface heat into the roll’s core, reducing the thermal gradient and the associated stress.

A forged steel roll, while harder, is more homogeneous and brittle under these thermal cycles. It is far more susceptible to developing “fire cracks”—a network of small surface cracks that can quickly deepen and lead to spalling (pieces of the roll surface breaking off).

2. Exceptional Wear Resistance at High Temperatures

The severe abrasion from the thick, rough-scale-covered slab would rapidly wear down a softer material. Alloying elements like Nickel, Chromium, and Molybdenum are added to the cast iron to form hard carbides (e.g., chromium carbides) within the metallic matrix. These carbides provide a robust, wear-resistant surface that can withstand the abrasive conditions of the roughing process for extended periods, ensuring consistent roll gap and dimensional control of the rough-bar.

3. inherent Damping Capacity

The graphite inclusions within the cast iron’s microstructure give it a high damping capacity. This means it can absorb vibrational energy. In the roughing process, where bites can be uneven and loads are shock-like, this damping reduces chatter and vibration, leading to a more stable rolling process and less dynamic loading on the mill machinery.

While cast iron’s properties are ideal for the roughing stage, they become liabilities in the finishing stands. The priorities shift from brute force and durability to precision and surface finish.

1. The Inability to Achieve a Mirror Finish

The very graphite inclusions that provide cast iron with its thermal shock resistance are its downfall for surface quality. When a cast iron roll is used to impart a final surface, the graphite particles can tear out or smear under the high, localized pressures of the final thin reductions. This creates microscopic imperfections on the steel strip’s surface. For many high-value products like automotive outer body panels or appliance exteriors, this is unacceptable. The surface must be virtually flawless.

2. Lower Stiffness and Hardness

Finishing stands require extreme dimensional precision, often within microns. Forged steel rolls, with their finer, more homogeneous microstructure, possess higher stiffness (modulus of elasticity) than cast iron. They deflect less under the rolling load, maintaining a more consistent and precise roll gap across the entire width of the strip. Furthermore, while cast iron is hard, advanced forged steel rolls can be treated to achieve even higher and more uniform hardness levels, which is essential for resisting the more refined wear in finishing and for retaining a polished surface.

3. The Demand for a “Clean Bite”

In finishing, the roll surface must be perfectly smooth to transfer a mirror-like finish to the steel. Forged steel rolls can be ground to a very fine surface finish and maintain it through their campaign. A cast iron roll, with its heterogeneous structure, cannot be polished to the same level or maintain it as consistently under the rolling pressures of the finishing stand.

| Property | Cast Iron Rolls (for Roughing) | Forged Steel Rolls (for Finishing) |

| Thermal Shock Resistance | Excellent (Graphite blunts cracks) | Poor (Prone to fire cracking) |

| Wear Resistance | Excellent (Hard carbides) | Superior (Harder, more uniform) |

| Damping Capacity | High (Stable under shock loads) | Lower |

| Surface Finish Quality | Poor (Graphite causes defects) | Excellent (Can be mirror-polished) |

| Stiffness (Rigidity) | Lower (More deflection) | Higher (Precise roll gap) |

| Economic Cost | Generally lower | Generally higher |

The division of labor in a rolling mill is a masterpiece of industrial optimization. Using cast iron rolls in the roughing stands is a pragmatic and highly effective strategy. It leverages the material’s superior toughness, thermal shock resistance, and wear characteristics to withstand the most punishing phase of the operation, all at a competitive cost. To use a more expensive, less thermally robust forged steel roll here would be inefficient and lead to premature roll failure.

Conversely, demanding the impossible from cast iron in the finishing stands—a perfect surface and supreme rigidity—would compromise the final product’s quality. The switch to forged steel rolls for the final stands is a necessary investment in precision, quality, and surface perfection.

In the end, the consistent use of cast iron rolls in the roughing stands is a testament to a simple, enduring engineering principle: select the material whose properties are best suited to the specific functional requirements of the task. It is a choice that ensures both the rugged reliability required to start the process and the exquisite precision needed to finish it.