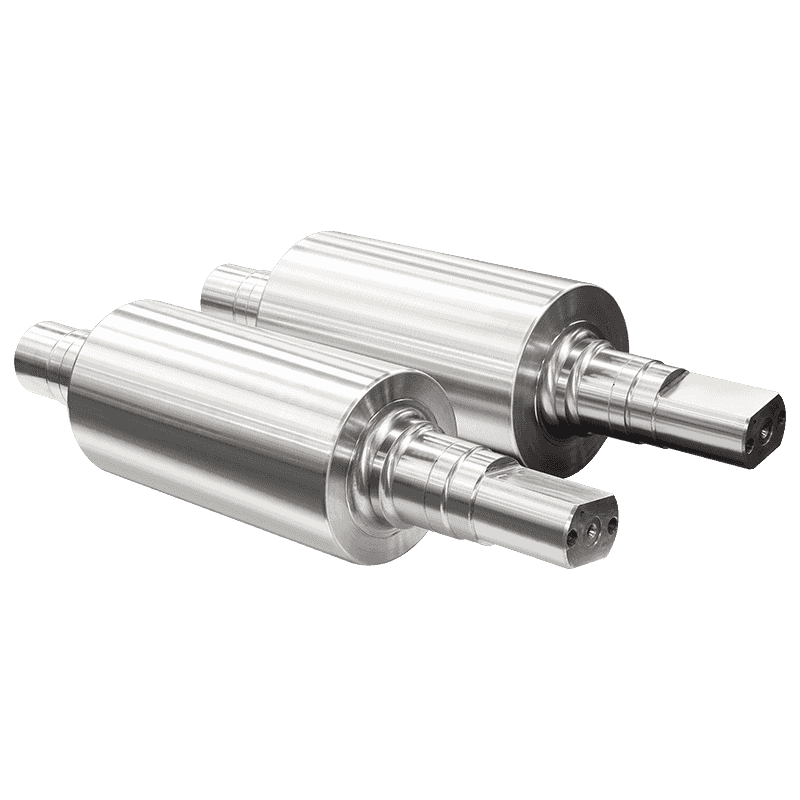

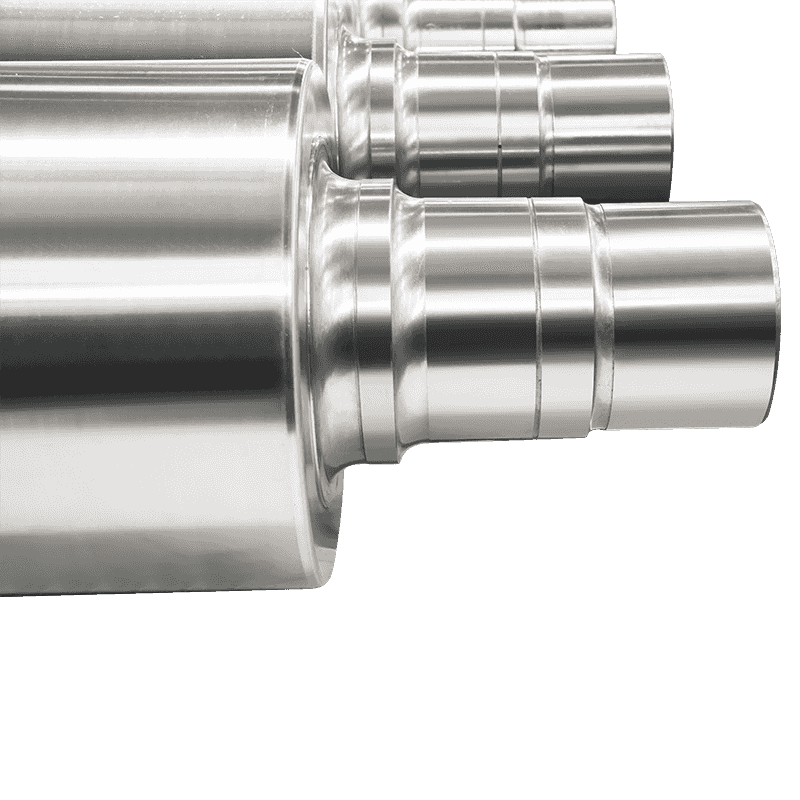

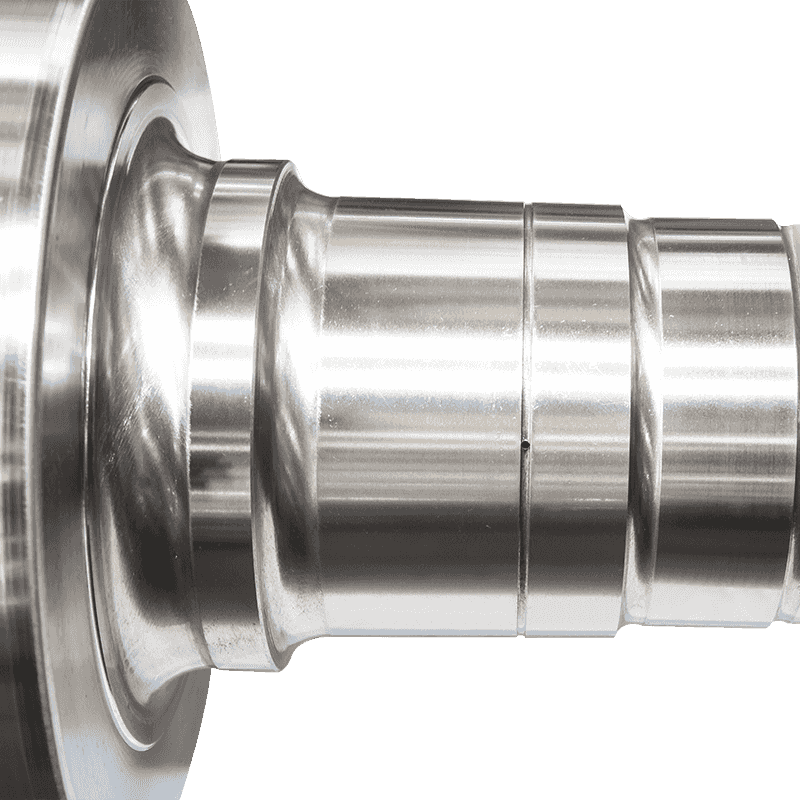

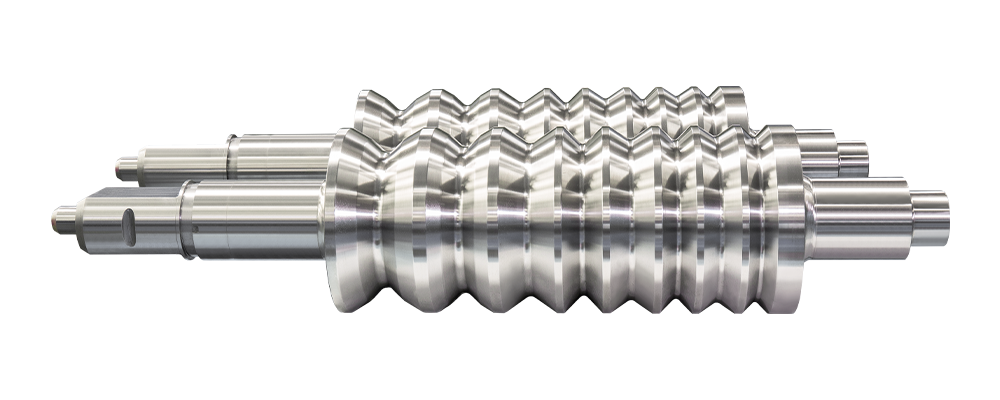

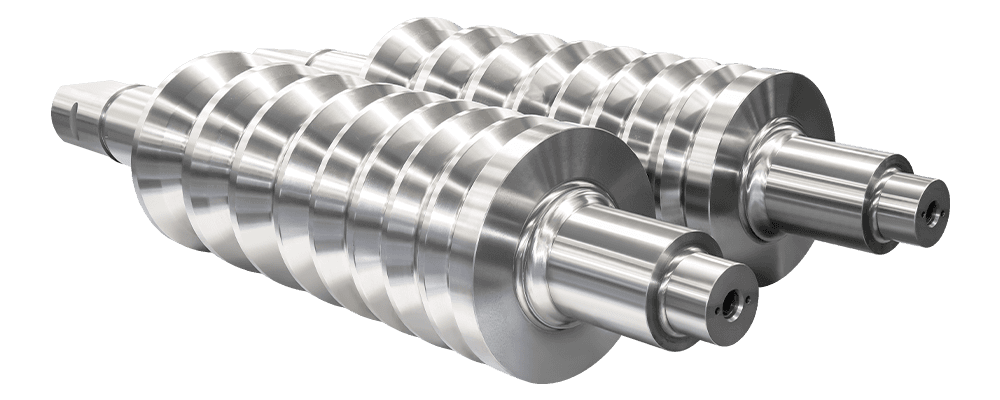

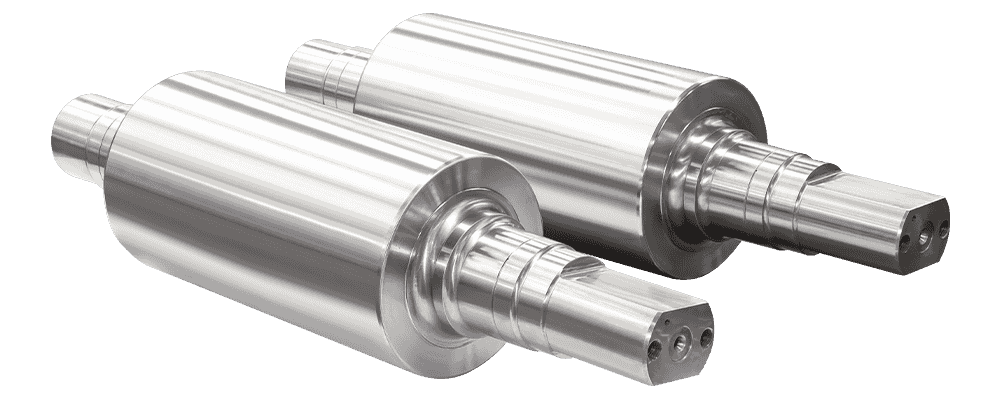

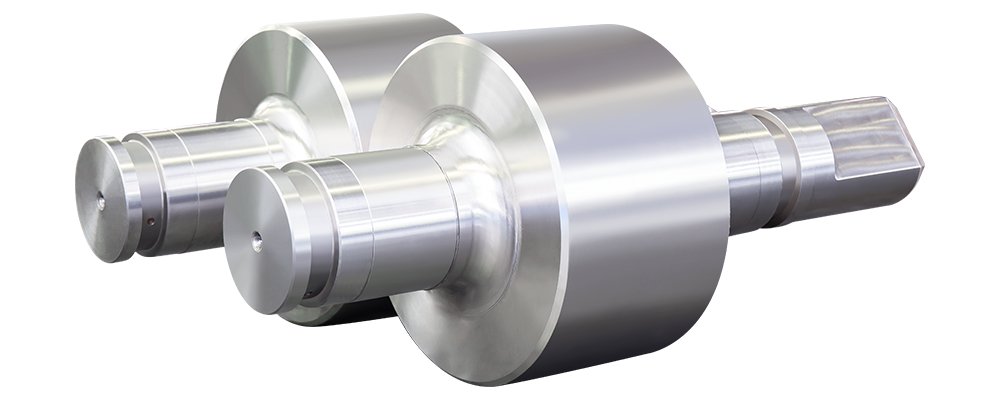

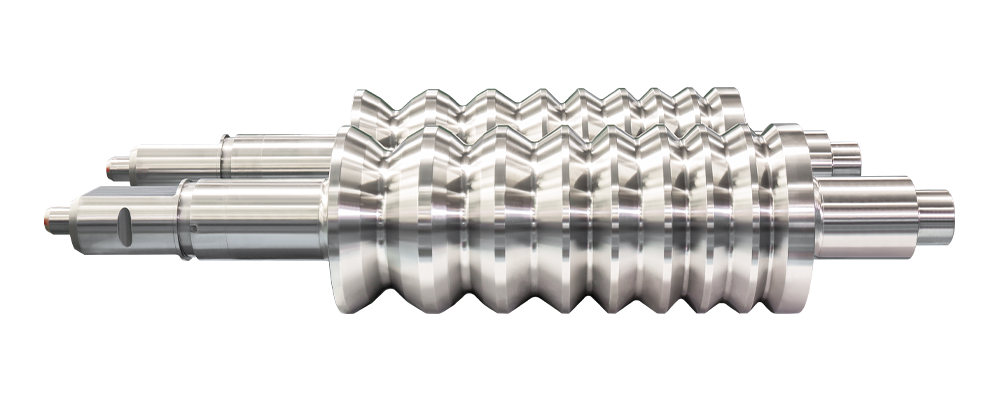

Infinitely Chilled Hard Cast Iron Rolls V (ICV) are made from a high nickel-chromium-molybdenum alloy that is extremely hard and wear-resistant to withstand heavy loads and high-wear environments. It has good thermal conductivity and heat dissipation, can dissipate heat evenly, prevent local overheating of the roll body, reduce thermal deformation and thermal stress, and improve rolling accuracy. It has anti-adhesion properties, which can reduce the adhesion of steel billets to the roller surface, reduce surface roughness, and improve the quality of rolled products. It has good spalling resistance, which can prevent the roll surface from spalling and improve the dimensional accuracy, surface finish, and consistency of rolled products. ICV rollers reduce rolling costs by reducing roll replacement frequency, reducing energy consumption, and reducing scrap rates. Infinitely chilled hard cast iron roll V for finishing work rolls is a high-performance, high-reliability roll that can significantly increase roll service life, improve rolled product quality, reduce rolling costs, and improve production efficiency.

Hardness HSD: 77-85

Nickel composition %: 3.01-4.8

Suitable for racks: refined and rolled

English

English 中文简体

中文简体