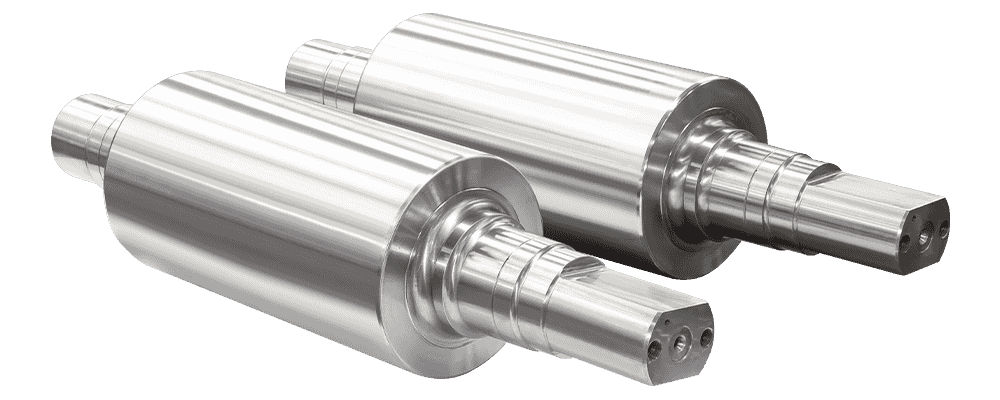

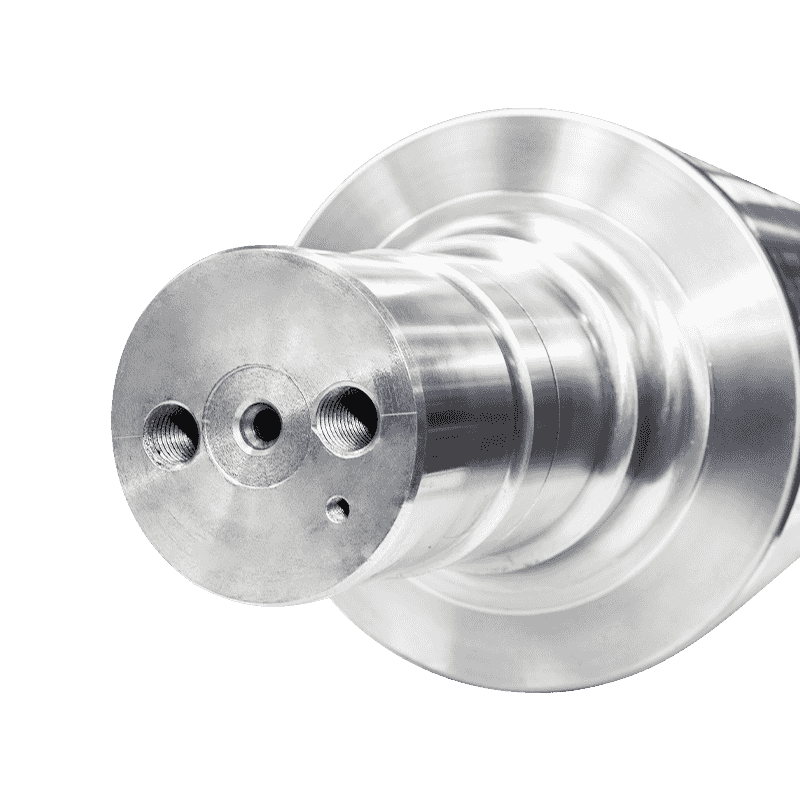

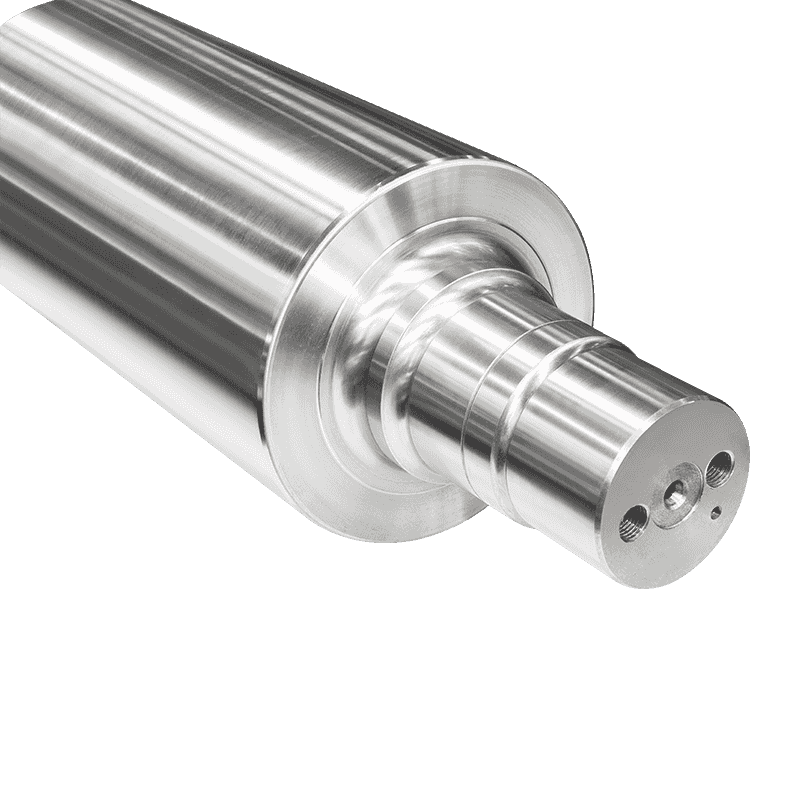

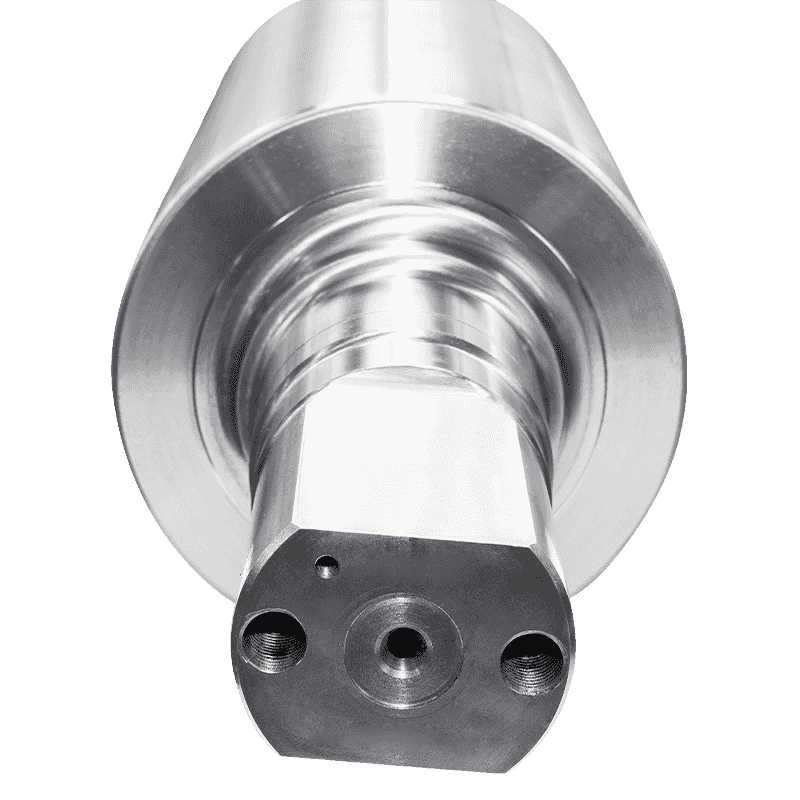

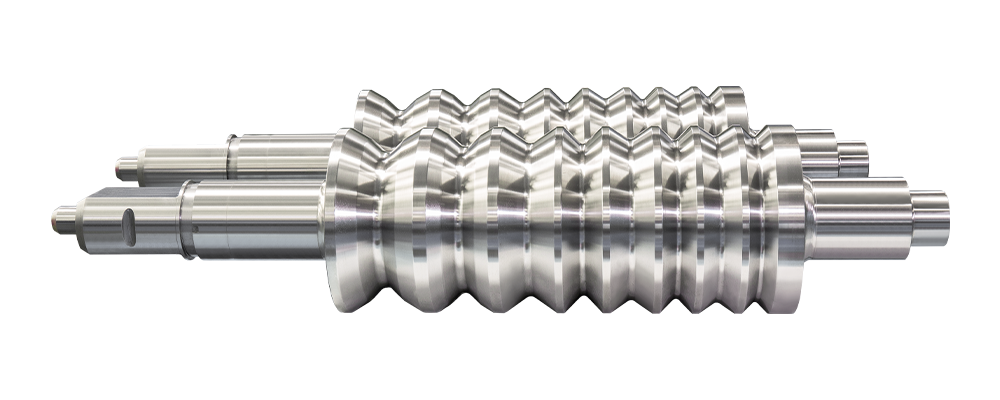

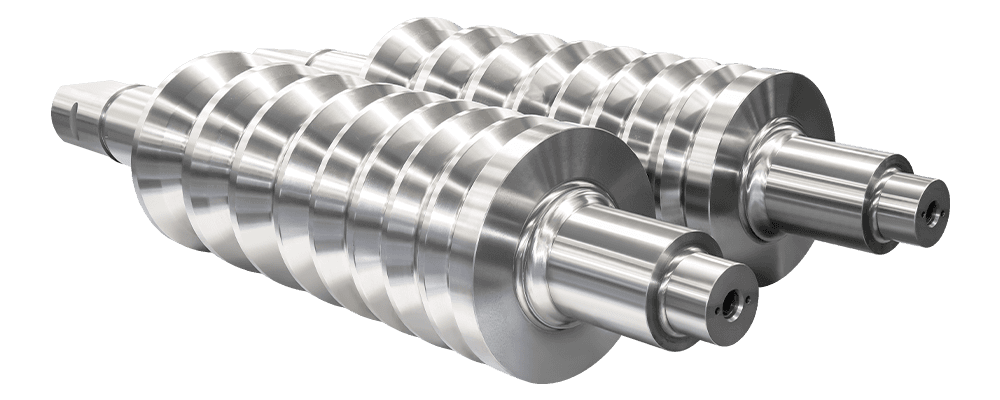

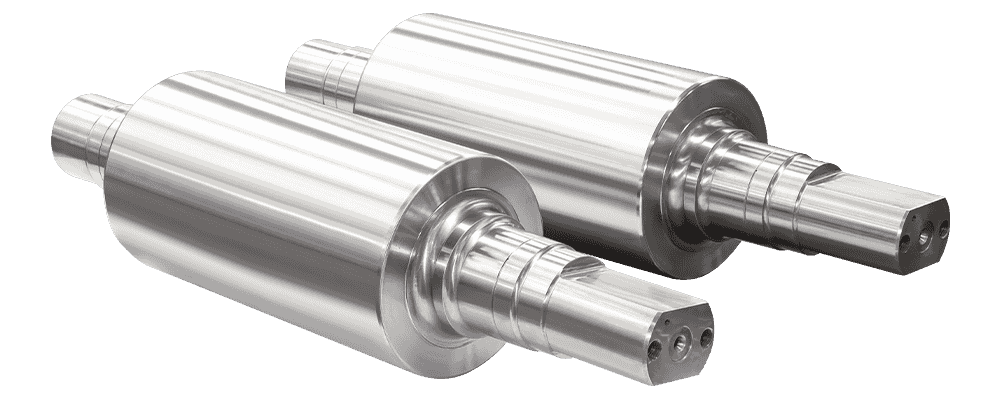

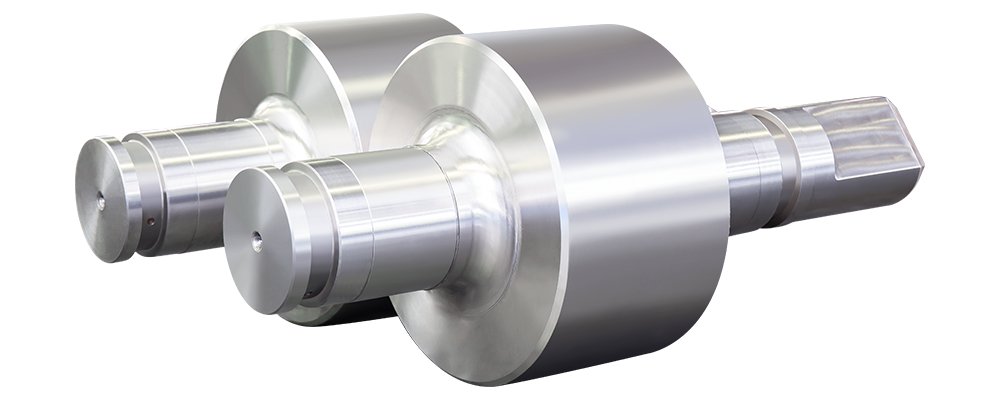

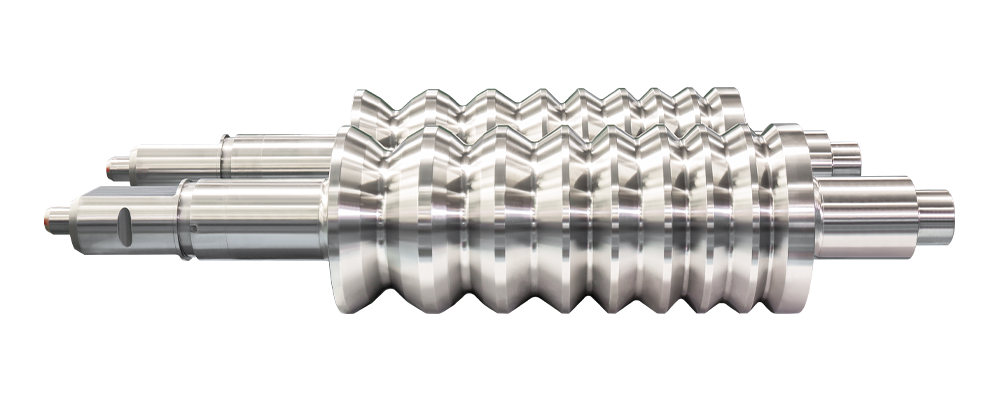

High Chromium Iron Roll III (HCrIII) is characterized by high hardness (75-90 HSD) and is typically used in rolling scenarios where wear resistance and high-temperature resistance are required. High chromium iron roller III has high hardness and can resist wear of the metal blank under high-speed friction, extending the service life of the roller. It has good anti-deformation ability and is not easy to deform even under high pressure, ensuring the stability of the rolling process and the dimensional accuracy of the product. It is suitable for various rolling machinery, including rough rolling mills, intermediate rolling mills finishing rolling mills, etc., to meet the rolling needs of metal billets of different materials and sizes. It can meet the requirements of the rolling process and has good cost-effectiveness.

Hardness HSD: 75-90

Nickel composition %: 0.7-1.7

Suitable for racks: refined and rolled

English

English 中文简体

中文简体