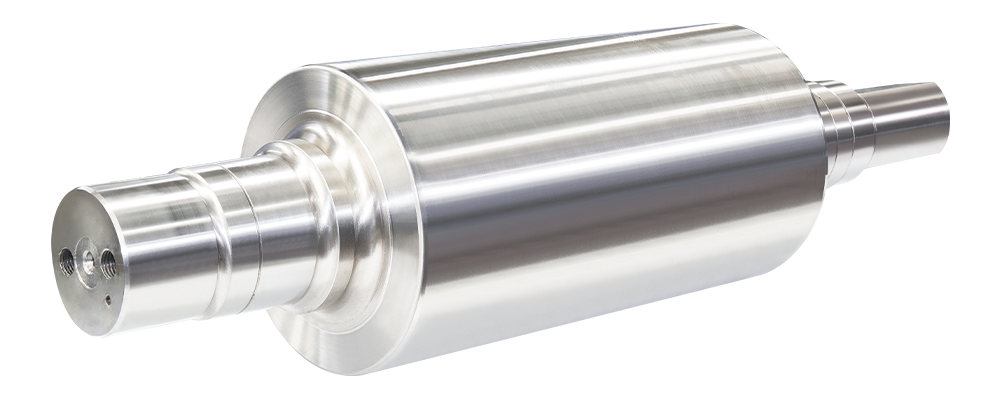

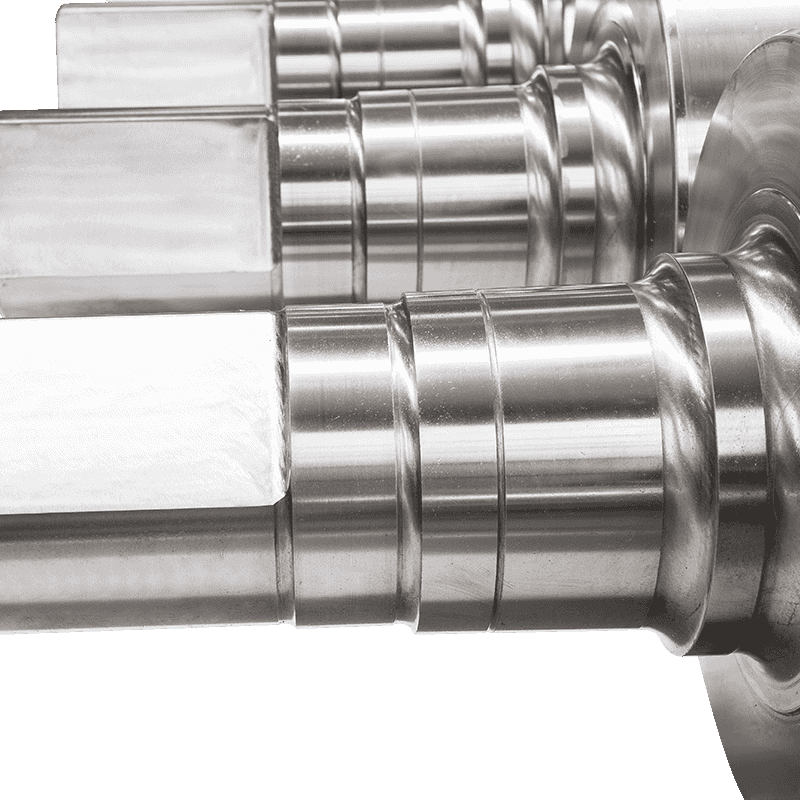

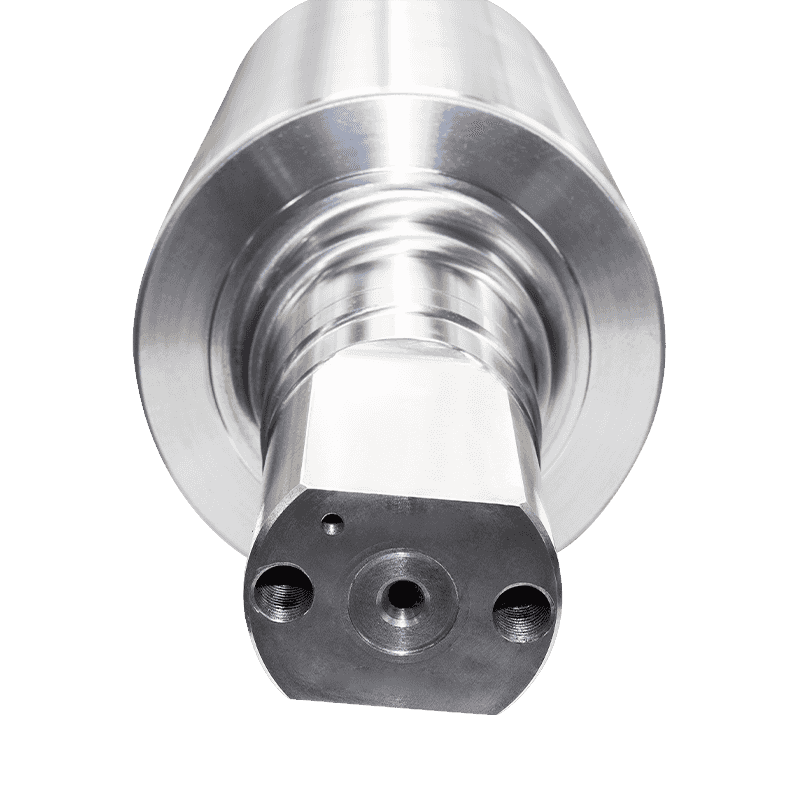

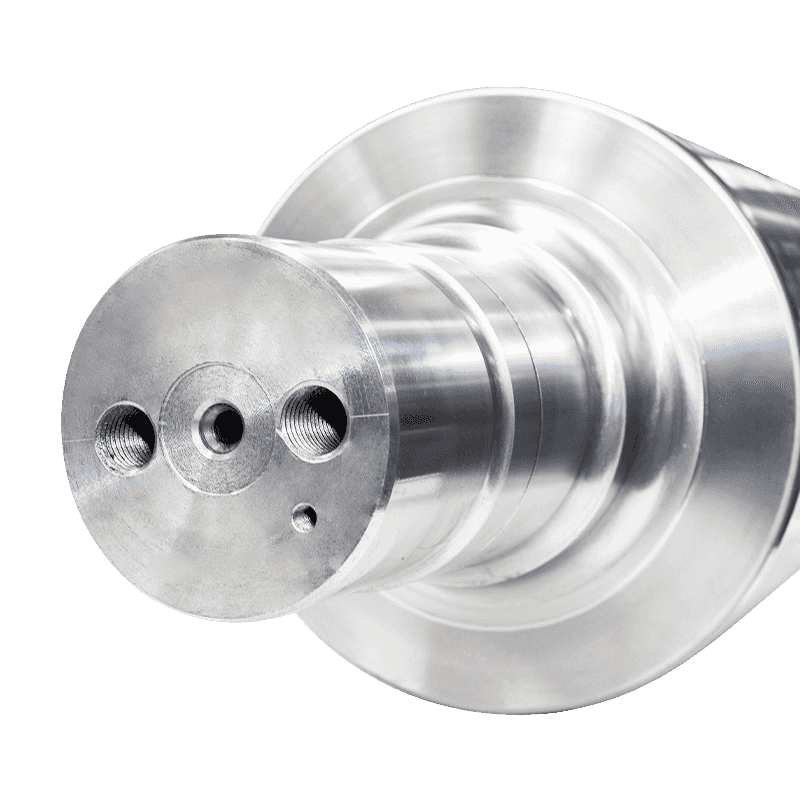

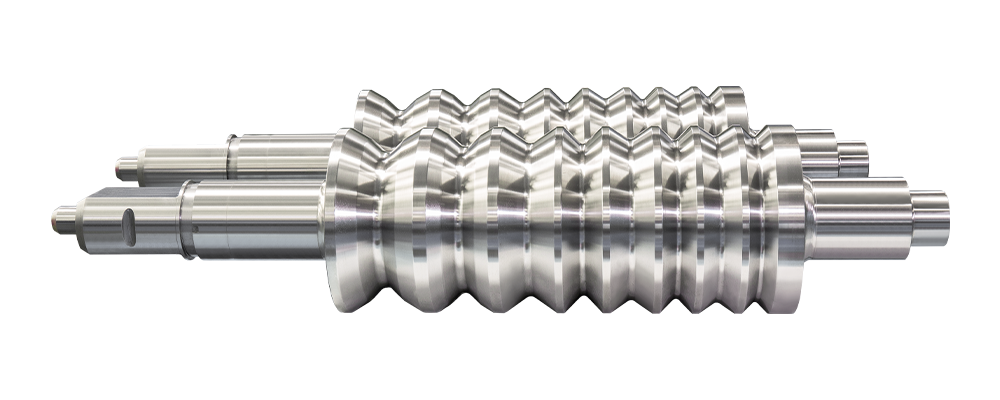

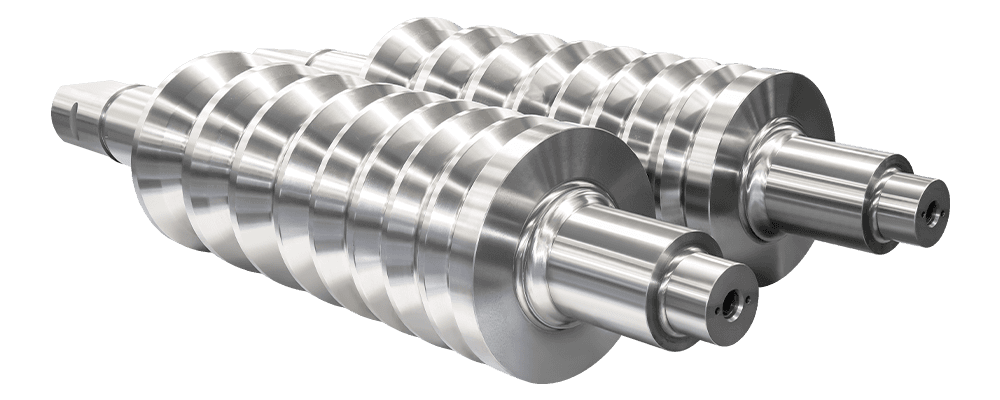

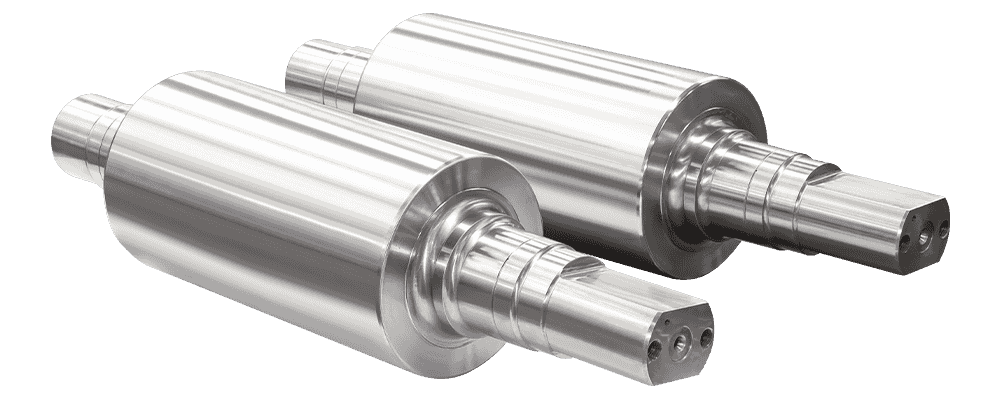

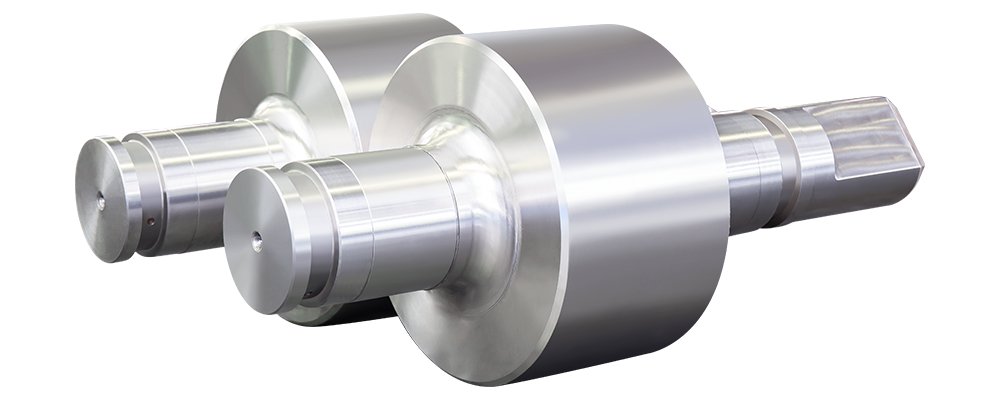

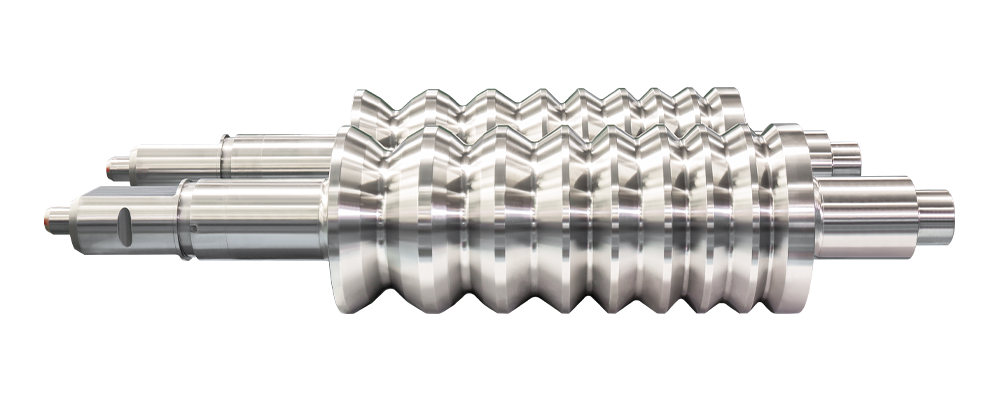

Chilled Hard cast iron rolls IV (CCIV) for wire rod mills are rolls made of high-strength, wear-resistant cast iron used for finish and cold rolling in wire rod mills. The hardness of the white layer of the CCIV rollers can reach HS 70-85. It has desirable wear resistance, which can extend the service life of the roller and reduce the frequency of roller replacement. It can withstand impact and vibration under high temperature and high pressure and is not prone to thermal cracks and breakage. It has good dimensional stability and is not easy to deform. It is widely used in various wire rod rolling mills, including high-speed wire rod rolling mills, high-precision wire rod rolling mills, and special steel wire rod rolling mills. Specific applications include: Commonly used in finishing rolling stands of wire rod mills for rolling high-strength, high-precision wire rods. Can withstand shock and vibration at high temperatures of 600-700°C and high pressure.

Hardness HSD: 70-85

Nickel composition %: 3.01-4.5

Suitable for racks: refined and rolled

English

English 中文简体

中文简体